I once picked a front door based on looks alone.

It was sleek, modern, and matched the villa’s brickwork perfectly.

But after one winter, it swelled, warped, and let cold air through the gaps. The supplier? Unreachable. The installer blamed the manufacturer. I was stuck.

If you’re choosing a door for your home, rental, or guesthouse, don’t just trust brochures or fancy showrooms.

I’ve worked with property owners, engineering teams, and contractors across the UK seen what lasts and what doesn’t.

This guide will walk you through 7 door manufacturers that are worth your time. Each one is verified, reliable, and actually builds doors here in the UK.

By the end, you’ll know which supplier fits your project and how to avoid costly regrets.

So let’s start!

Quick Comparison Chart

Before we dive into the full breakdown, here’s a quick side-by-side look at the 7 UK front door manufacturers you’ll meet in this guide. This gives you a snapshot of what each one offers and where they may fall short so you can skim before you dig deeper.

| Manufacturer | Year Established | Location | Best For | Key Strengths | Drawbacks / Not Ideal For |

| Solidor | 2004 | Stoke‑on‑Trent, Staffordshire | High‑end homes, B&Bs, guesthouses | Timber core, solid weight, premium security features | Higher price point; fewer budget‑friendly options |

| Comp Door | 2021 | Newcastle‑under‑Lyme, Staffordshire | Energy‑conscious builds, modern orders | Strong insulation, solid timber core, fast-growing innovative brand | Still evolving style variety and market presence |

| Endurance Doors | 2010 | Brigg, North Lincolnshire | Coastal builds, heavy usage | Moisture barrier, 85+ styles, certified locks | Overwhelming design choices without installer guidance |

| Rockdoor | 1996 | Lancashire, UK | Security‑focused low‑maintenance use | Aluminium‑reinforced core, high energy ratings | Foam core may not suit traditional material preferences |

| Door‑Stop Intl. | 2008 | Nottinghamshire, UK | Fast installs, rental builds | Quick delivery, affordable, installer‑friendly | Limited customization; not ideal for luxury projects |

| Longden Doors | 1838 | Newton Aycliffe, County Durham | Heritage and high‑custom builds | Handcrafted timber, fire/acoustic-rated options | High cost and long lead time for bespoke projects |

| Hallmark Panels | 1990 | East Yorkshire, UK | Volume orders, style diversity | 2,000+ colour options, strong security, consistent supply | Too many choices can cause early-stage decision fatigue |

Now that you’ve seen the quick overview, let’s move on to the detailed reviews for each manufacturer.

1. Solidor

Solidor launched in 2004 and is located in Stoke‑on‑Trent, Staffordshire. They’ve built their reputation around the 48 mm solid timber core composite door, which delivers real weight, insulation, and longevity backed by PAS 24‑2016 security standards and Secured by Design accreditation. I’ve seen these doors in villas and B&Bs, and their quality rarely disappoints .

They serve across the UK through approved installers, focusing solely on composite front and back doors that meet British regulations and expectations for durability and performance.

Product Types & Build Quality

- Solid Timber Core Composite Door: A 48 mm thick hardwood centre, completely encapsulated by ABS skins, offering superior insulation and resistance to forced entry.

- Traditional Range Front Door: Classic designs in textured wood‑grain finishes, available in mobility threshold options for easier access.

- Contemporary Italia Collection Door: Sleek minimalist styling, bold colours, and modern glazing suited to modern or heritage properties .

Design & Customisation Options

You’ll find over 27 colours, dual‑colour interiors and exteriors, and various glazing styles from bevelled leaded glass to textured panes. I’ve enjoyed walking clients through their Door Designer tool; seeing a mock‑up of their actual door gives them peace of mind. Hardware choices include letterboxes, knockers, and Ultion or Avantis locks for added confidence .

Who They’re Best For

- Villa & High-End Homeowners: Heavy doors with good thermal performance and aesthetic options for elegant entrances.

- B&Bs & Small Hotels: Strong security credentials and attractive designs handle frequent use well.

- Properties in Wet or Windy Regions: Waterproof frame profiles and robust cores that resist swelling or warping.

Manufacturing Location & Facilities

Solidor manufactures all their doors in Stoke-on-Trent, Staffordshire. Production isn’t outsourced, which means they control the full process from core to finish.

The factory uses CNC machinery, timber processing lines, and in-house finishing stations. Quality checks are built into each stage before anything leaves the facility.

Contact & Support Info

- Address: Solidor®, Meir Park, Whittle Rd, Stoke on Trent, ST3 7TU .

- Phone: 01782 847 300.

- Website: solidor.co.uk

- Support: Enquiry form, access to certified installers, brochure downloads, and security test video resources on the website.

Final Verdict

When I first recommended Solidor to a villa owner, she noted how solid the door felt and the peace of mind that came with Ultion lock and PAS 24‑2016 certification. If you’re after a door that’s built to last, looks good in person, and performs in UK weather, Solidor delivers.

However, this level of quality comes with a higher price. If you’re budget-conscious, there are more affordable options but few offer the same UK-made build and long-term reliability.

2. Comp Door

Comp Door is based in Newcastle-under-Lyme, Staffordshire, and focuses on building high-performance composite front doors. Their standout feature is a solid Albasia Falcata timber core, combined with CoolSkin technology and TriSeal frames for long-term durability.

They operate entirely in the UK with a strong focus on customer service and installation support. I’ve heard positive things from both installers and end users who trust the build quality and like the wide design choices.

Product Types & Build Quality

- Solid Timber Core Composite Door: Built with a 48 mm laminated timber core for better strength and thermal insulation than foam-filled alternatives.

- French Composite Door: Double-door style with the same solid core, perfect for wide entrances or letting in natural light.

- Composite Stable Door: Horizontally split design lets the top and bottom open independently ideal for kitchens, pets, or country homes.

Design & Customisation Options

There are over 250 colour combinations, dozens of styles, and both modern and traditional looks. You can mix interior and exterior colours, choose from glazing options, and even add auto-locking features.

I’ve walked clients through their online Door Designer, and it genuinely helps visualize what the door will look like. It’s simple but effective and removes a lot of guesswork.

Who They’re Best For

- Homeowners Wanting Energy Efficiency: Low U-values help keep homes warm and lower heating costs.

- Small Hotels or B&Bs: Solid build and auto-lock make check-ins easier and safer.

- Properties in Harsh Climates: Weather-resistant skin and seals perform well in rain, wind, and temperature changes.

Manufacturing Location & Facilities

All Comp Door products are made at their Staffordshire facility. Production includes timber prep, glazing, and sealing all done in-house.

To me, that’s a major plus. It means better control over quality and fewer problems with batch inconsistency or delivery delays.

Contact & Support Info

- Address: Comp Door Ltd, London Road, Chesterton, Newcastle-under-Lyme, ST5 7PL

- Phone: 01782 340 444

- Email: info@compdoor.co.uk

- Website: www.compdoor.co.uk

- Support Tools: Door Designer tool, installer finder, downloadable brochures, and live tracking via trade portal

Final Verdict

I recommended Comp Door to a B&B owner last year, and the feedback was great easy to install, low maintenance, and customers noticed the door’s quality right away. For me, it’s a brand that blends performance with good design options.

However, the price is a bit above entry-level ranges. But if you’re after reliability and support from a UK manufacturer, it’s a smart long-term choice.

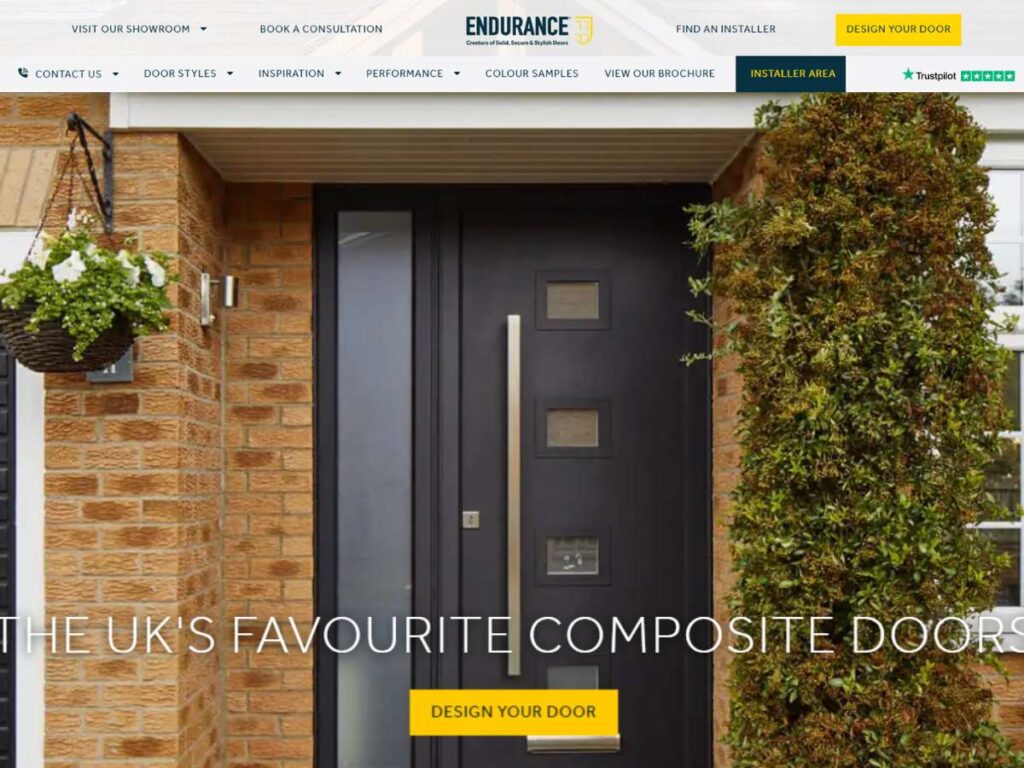

3. Endurance Doors

Endurance Doors is a UK-based manufacturer founded over a decade ago, known for high-security composite doors built from a 48 mm engineered timber core made of 17 cross‑bonded laminates. Their doors are around 10% thicker than many competitors, with built-in Moisture Barrier System (MBS) and CoolSkin surface to resist weather damage and warping .

Their network of over 300 approved installers covers the UK; I’ve seen their doors installed at coastal homes and rural inns. Several clients told me they trusted the consistent quality and long-term performance, especially in wet or windy regions .

Product Types & Build Quality

- Classic Collection Composite Door: Traditional Victorian/Georgian styling with a thick insulated core for thermal retention and secure multi-point locking.

- Urban Collection Composite Door: Sleek, minimalist designs with bold glazing panels and modern hardware for contemporary properties.

- Country Collection Composite Door: Shiplap style designs in rustic finishes, ideal for heritage homes and properties needing charm with durability.

Design & Customisation Options

Endurance offers more than 85 door styles, 17+ colours, and matching interior/exterior finishes. You can choose glazing, handles, knockers, and frame styles to match your property’s aesthetic.

I really appreciated their HomeView Door Designer tool: I’ve walked people through it and it removes guesswork. Seeing a photo of your house with the proposed door gives reassurance and a visual that most clients value .

Who They’re Best For

- Homeowners Focused on Security: Thick timber core, Secured by Design certification, and £2,000 lock guarantee appeals to safety-minded buyers.

- Villas, B&Bs or Inns: Strong materials stand up to heavy traffic, and consistent build reduces maintenance calls.

- Coastal or Exposed Sites: CoolSkin and MBS protect the door from moisture and salt-air effects.

Manufacturing Location & Facilities

Endurance operates their own UK factory in Brigg, North Lincolnshire. Every stage from laminated core assembly to foiling and finish is done on-site, ensuring consistency.

There’s something reassuring about a factory that controls every step. When I’ve checked production centres like this, quality and delivery times are much more reliable.

Contact & Support Info

- Address: Endurance Doors, Atherton Way, Brigg, North Lincolnshire, DN20 8AR

- Phone/Email: sales@endurancedoors.co.uk

- Website Features: Online Door Designer, installer locator tool, downloadable brochure, and trade portal access

Final Verdict

Endurance doors performed well in a cold, coastal project I supported—their moisture-resistant core solved previous swelling issues. Two winters in, no problems.

However, their wide range of styles can be overwhelming without a clear design plan. Using their visualizer or asking your installer can help narrow it down.

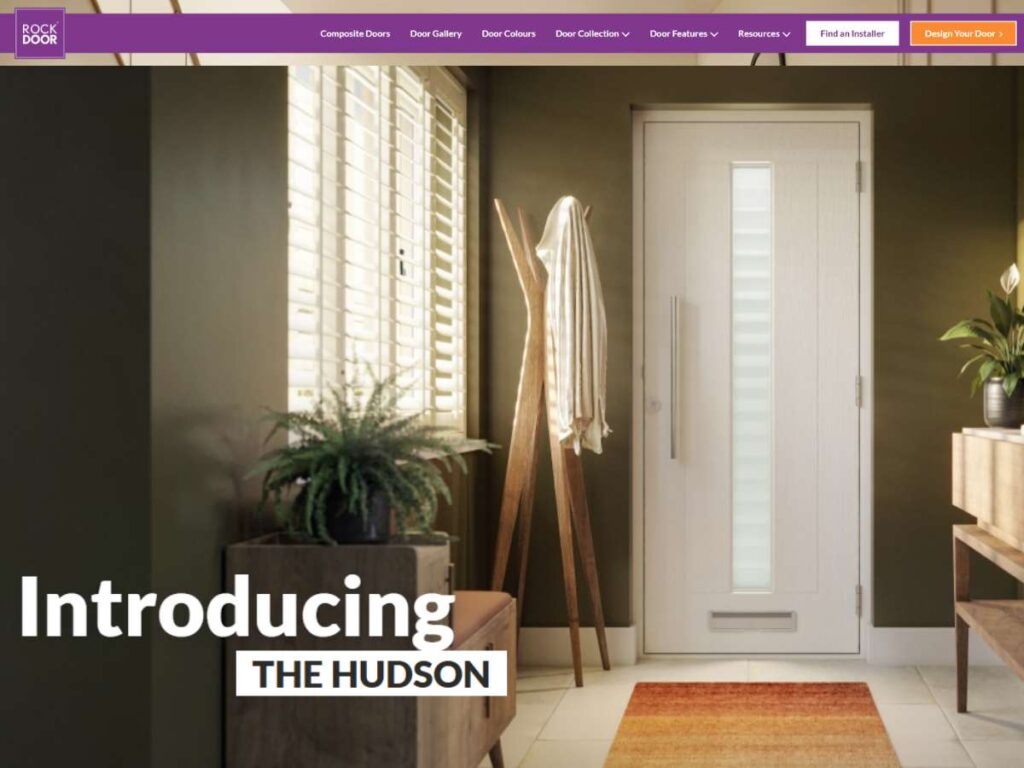

4. Rockdoor

Rockdoor began in 1996 in Lancashire and claims to be the original composite door manufacturer in the UK. They made over half a million doors using high‐density foam cores, reinforced with aluminium and carbon fibre, which delivers strength, thermal efficiency, and long-term performance. I’ve inspected installations in coastal cottages where Rockdoor’s resistance to moisture and its consistent build quality clearly stood out.

They install nationwide through a network of approved installers and hold accreditations like PAS 23/24 and Secured by Design that reinforce their focus on security.

Product Types & Build Quality

- Front Composite Door: High-density polyurethane foam core reinforced with carbon fibre and aluminium for strength. Multi-point hook locks and uPVC skins offer weather and vandal resistance.

- Stable Composite Door: Horizontally split door allowing separate operation of top and bottom halves. Ideal for ventilation while maintaining security.

- French Composite Door: Double-leaf design with secure glazing for stylish garden access. Made with the same foam and reinforcement structure to match front doors.

Design & Customisation Options

Rockdoor offers over 30 door styles, 13 colour choices, and more than 100 glass patterns. You can mix interiors and exteriors colour, choose handles, threshold types, and door furniture to suit your taste.

I remember walking a homeowner through the Rockdoor gallery seeing the 3D renders of her own home made her confident in her choice. It’s personal and visual, so you’ll know what you’re ordering.

Who They’re Best For

- Security-Minded Homeowners: Reinforced frames and Sold Secure locks provide peace of mind.

- Houses Near Roads or Windy Areas: Foam core and tight seals reduce noise and prevent warping.

- Stylish Renovations or Guesthouses: Wide style and glass combinations fit modern and period designs.

Manufacturing Location & Facilities

Rockdoor manufactures all doors at their high‑tech facility in Lancashire, UK. Their production is highly automated, combining foam core formation, aluminium reinforcement, and glazing into one cohesive process.

I appreciate that they don’t cut doors to size which can weaken them. Instead, everything is made-to-measure to maintain structural integrity and reliability.

Contact & Support Info

- Address: Rockdoor Ltd, Blackburn area, Lancashire, UK

- Phone: 0345 313 1012 (via GAP Ltd contact) gap.uk.com

- Website: www.rockdoor.com

Final Verdict

Rockdoor delivered strong security and low maintenance on a project I recommended no swelling or fading after 2 years of heavy use. It handled weather and wear with no issues.

However, the foam core can feel less traditional than timber and may seem rigid to some. If durability, insulation, and security matter most, it’s a standout option.

5. Door-Stop International

Door‑Stop International, launched in 2008, operates from Nottinghamshire and aims to simplify composite door buying in the UK market . They brought the idea of “ready-to-fit” design orders to life and are known for fast delivery and user-friendly tools like their online Door Designer.

They help installers and homeowners find quality composite or solid-core doors quickly no fuss. I’ve seen their doors arrive on-site in just three working days, making life easier when deadlines are tight.

Product Types & Build Quality

- GRP Skinned Composite Door: Made with a glass-reinforced plastic (GRP) outer skin over a solid timber core for strength and weather resistance. GRP is used in marine applications, so it handles rain and wind well .

- Solid Core Composite Door: Contains a continuous timber core for better thermal insulation and sound dampening. Feels firmer in hand and helps reduce energy bills.

- Fire Doorset Composite Door: Offers fire ratings alongside composite benefits. Includes smoke seals and intumescent strips for safety in multi-unit buildings .

Design & Customisation Options

They offer 13 colour options, multiple door styles (traditional and modern), and extensive hardware finishes. You also get separate interior/exterior colour choices and a huge range of glazing options.

I guided a client through their online Door Designer tool, and seeing their exact front door digitally placed on their house made all the difference. It reduces surprises and builds confidence before ordering.

Who They’re Best For

- Value‑Focused Homeowners: Stylish, secure doors at an affordable price point and fast turnarounds.

- Engineers or Fit‑Out Teams: 3-day delivery and factory‑hung sash makes installation quicker and easier.

- Projects with Tight Schedules: Whether it’s a renovation or small hotel job, their fast delivery reduces delays.

Manufacturing Location & Facilities

All Door‑Stop doors are made in the UK, at their Nottinghamshire production site. The plant is optimized for efficient throughput from core assembly to finishing.

I appreciate their lean operation because it speeds up delivery and reduces errors you get what you order, when you expect it.

Contact & Support Info

- Address: Nottinghamshire, UK (Door‑Stop composite factory)

- Phone: via installer/distributor commonly listed on supplier sites for trade orders

- Website: www.door-stop.co.uk

Final Verdict

Door‑Stop came through on a tight timeline . Their fast factory turnaround and ready-to-fit delivery solved a last-minute need. The installation was smooth, and the client was happy.

However, their range is more limited than premium brands. For quick, UK-built doors with solid performance, they’re a reliable pick when time matters.

6. Longden Doors

Longden Doors was established in 1838 and is based in Newton Aycliffe, County Durham. They specialize in crafting solid hardwood external doorsets in the UK, using correctly seasoned timber for stability and acoustic performance . I’ve visited their workshops and was struck by the attention each door receives a quality that shows in the finished product and long-term satisfaction.

They serve heritage projects, luxury homes, boutique hotels, and bespoke residential developments, offering tailored service from design through to installation management .

Product Types & Build Quality

- Classic Panelled Timber Doorset: Handcrafted in traditional panel styles (Chippendale, Sheraton, Hepplewhite), offering fire-rated options up to FD60.

- Boarded or Stable Doorset: Vertical or horizontal board design, ideal for country properties and heritage restoration.

- Framed Glazed Doorset: Glazed panels integrated into hardwood doorset, combining light, thermal performance, and acoustic control.

Design & Customisation Options

You can choose from a wide range of hardwood species oak, walnut, iroko, and Accoya with custom finishes like stain, paint, or oil. Their designers guide you through panel layouts, style choice, and finishes to match your project’s aesthetic.

I once helped a homeowner choose timber species and hardware; seeing actual wood samples made the decision feel personal and reassuring. Longden’s process felt collaborative not off-the-shelf.

Who They’re Best For

- Owners Of Heritage Homes: Traditional joinery replicates original detailing with modern fire and acoustic ratings.

- High-End Villa Or Hotel Projects: Luxury materials and finish deliver real presence and durability.

- Architects & Integrators Needing Certification: Fire-rated, acoustic, and size-specific doors built to spec.

Manufacturing Location & Facilities

All doors are made in their County Durham factory at Aycliffe Business Park. The workshop includes timber seasoning kilns, CNC joinery, finishing rooms, and quality checks before shipment .

I respect that they control every step: it translates into consistency in both finish and delivery schedules and it shows in fewer installation surprises.

Contact & Support Info

- Address: Longden Doors UK Ltd, Whinbank Park, Unit 5b, Whinbank Road, Newton Aycliffe, Co. Durham, DL5 6AY

- Phone: 01325 582 583

- Email: sales@longdendoors.co.uk

- Website: longdendoors.co.uk

Final Verdict

When designing a restaurant with heritage charm, one client insisted on matching existing period detailing. Longden delivered accurate profiles in solid oak with acoustic seals, and the result has proven timeless and robust.

However, their doorsets come at a premium and require lead time for design and machining. But if you’re aiming for craftsmanship, authenticity, and long-lasting performance, Longden is unmatched in UK timber doors.

7. Hallmark Panels Ltd

Hallmark Panels Ltd has over 30 years of experience as a UK composite door manufacturer, offering GRP (glass-reinforced polyester) doors with a polyurethane foam core reinforced by aluminium and steel. They offer one of the largest design ranges in Britain and are highly rated by professional installers across the country.

Their doors meet security and building standards including PAS 24, Secured by Design, Document Q and ISO 9001. That gives you confidence in product support and quality audits from start to finish.

Product Types & Build Quality

- Elite Composite Front Door: Reinforced foam core with steel‑reinforced frame, multi-point locks, and high-impact GRP skin for strength and weather resistance.

- Stable Composite Door: Split horizontally with independent top and bottom access so you can ventilate without losing security.

- Double Rebate Composite Door: Wider door slab for enhanced insulation and rigidity, suitable for oversized or period-style entrances.

Design & Customisation Options

You can choose from over 150 door designs, 2,000+ colour options, and hundreds of glazing patterns. Interiors and exteriors can be different colours, with premium matt finishes available.

When I walked a villa owner through their online Hallmark Now designer, the sheer choice made her nervous but after pairing styles with her home, she felt reassured. And handling actual colour bonded samples added real confidence before ordering.

Who They’re Best For

- Busy Homeowners or Small Hotels: The vast range means you can match your building style without compromise.

- People In Changing Climates: GRP skin resists fading, moisture, and thermal movement up to 3 mm.

- Those Needing Certification: Doors certified to PAS 24, Document Q, Secured by Design ideal for regulated properties or social housing.

Manufacturing Location & Facilities

Hallmark doors are made in several extended facilities across the UK, including highly automated production lines using CNC routers, powder-coating booths, and an in-house glass toughening plant.

I value the scale they’ve invested in it reduces lead time and improves colour consistency, even on large orders across different locations.

Contact & Support Info

- Address: Hallmark Panels Ltd, HQ at Hull/Thorne area, East Yorkshire

- Phone: 01482 781 111

- Email: enquiries@hallmarkpanels.com

- Website: hallmarkpanels.com

Final Verdict

Hallmark worked well for a multi-unit project factory bonding and consistent glazing kept every door uniform and hassle-free. Everything fits cleanly across all units.

However, the wide range of options can slow things down if you’re unsure on design. For UK-built, secure, and visually consistent doors with certification, they’re hard to beat in this price range.

Looking for a Front Door Manufacturer Outside the UK?

Not every project fits what UK suppliers can offer. Some buyers need faster lead times, wider design flexibility, or more competitive pricing for bulk orders. That’s why many contractors, villa owners, and hotel developers consider importing from overseas especially from China.

One option frequently considered is Vallisco, a custom manufacturer based in China that supplies doors and windows globally. Their capabilities often appeal to buyers who need flexibility beyond standard UK specs.

Here’s what manufacturers like Vallisco typically offer:

- Custom front doors with adjustable sizing and styles

- Matched door and window sets for consistent exterior design

- Bulk manufacturing ideal for multi-property or commercial builds

- Worldwide shipping support, including English-speaking coordination teams

- Experience with B&Bs, resorts, and modern villas

Importing from China doesn’t have to be complex especially when you’re working with a team that already supports international projects. If you’re open to exploring global options, it may be worth seeing what’s possible.

Want to explore your options with Vallisco? Contact us now.

Conclusion

I started this journey thinking a door was just a door. It wasn’t.

Now I know better and after reading this, so do you.

We’ve covered 7 UK manufacturers who actually build their doors here. You’ve seen what they offer, how they differ, and who they’re best for.

But if none of them feel like the right fit don’t worry. You’ve got another option.

At Vallisco, we make custom doors in China with more flexibility, better pricing, and worldwide delivery.

Ready to find the door that’s right for you? Contact Vallisco today!

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

- Doors & Windows for Apartments & Hotels

- Garage Door

- Barn Door

- Sliding Window

- Thermal Break Aluminum Window

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.