Last year, a client in Europe asked us to help replace all the double doors in their seaside inn. We tested 3 suppliers before we found one that delivered what we needed.

I learned that most problems come from the first decision: who you order from.

You can trust this list. I’ve been in the doors and windows business long enough to know who delivers good work and who doesn’t. This review is based on orders I’ve placed, calls I’ve made, and follow-ups I’ve done.

In the next few minutes, you’ll see 8 companies that supply double doors for homes and hospitality projects. If you’re looking for a supplier you can actually work with, you’ll find one here.

It starts with one good choice.

So let’s get down to it!

Quick Comparison Chart

If you’re shortlisting double door suppliers for hospitality or residential projects, this table gives you a side-by-side view of what each manufacturer focuses on and offers best.

| Manufacturer | Product Focus | Customization | Manufacturing Scale | Sustainability Efforts | Best For |

| Hörmann | Industrial, garage, fire-rated | Medium | Very High | Energy-efficient doors, recycling, training | Commercial builds, large-scale residential |

| Masonite International | Fiberglass, wood, steel, molded | Medium | Very High | Wood reuse, low-VOC finishes | Volume builds, standard spec projects |

| Vallisco | Aluminium, glass, pivot, sliding | High | Medium | Eco packaging, clean materials | Villa, boutique hotels in Asia & Europe |

| Internorm | Aluminium, timber-aluminium, sliding | High | Medium | Passive house certified, low-impact coatings | Energy-efficient homes, mountain/lodge builds |

| Oknoplast | PVC, aluminium, French, entry | Medium | High | PVC recycling, solar energy use | EU-based homes, B&B renovations |

| Secco Sistemi | Steel, bronze, corten, custom designs | Very High | Medium | Recycled metal, design longevity | Design-led villas, boutique luxury projects |

| Andersen Corporation | Composite, wood, fiberglass, French doors | High | High | Fibrex material, waste recycling | High-end energy-focused residential/hospitality |

| ProVia | Fiberglass, French, steel, storm doors | Medium | Medium | Recycled cores, lean production | U.S. villa projects, small hotels |

Use this chart to match your project’s size, style, and supply needs. For in-depth details, check each profile below!

1. Hörmann

Website: https://www.hoermann.com

Location: Steinhagen, Germany

I first heard about Hörmann during a hotel renovation project in Europe. A contractor friend said they were fast, reliable, and easy to talk to. That got me curious.

Hörmann has been making doors since 1935. That’s nearly 90 years of doing one thing well. They’re still family-owned and operate across Europe, Asia, and even North America. They’ve grown from a small workshop into one of the most trusted door manufacturers in the industry.

Product Range

- Double Entry Doors: These are insulated, secure, and come in modern or classic designs. Great for homes and hospitality buildings.

- Industrial Doors: Roller shutters, loading dock doors, and high-speed options. Built for warehouses and commercial spaces.

- Garage Doors: Automated sectional and up-and-over styles, often used for villas and residential blocks.

- Fire-rated Doors: Built to meet strict safety rules, these doors are used in hotels, stairwells, and high-occupancy buildings.

- Steel Internal Doors: Tough and low-maintenance. Often used in service areas, plant rooms, and basements.

Manufacturing Capabilities

Hörmann owns and runs over 25 factories across Europe. Most of their doors are made in-house, not outsourced. That gives them control over timing and quality.

They make thousands of units a day, and they support OEM for projects. You can choose custom colors, finishes, sizes, and accessories.

They also use advanced machinery to speed up processes and keep everything consistent. That helps with larger orders or repeat orders over time.

Sustainability & Ethical Practices

- Eco Material Choices: They use recyclable steel, aluminum, and insulation foams that meet energy standards.

- Energy-Efficient Plants: Many of their factories run on low-energy systems to cut electricity use.

- Packaging Reduction: They limit waste by using returnable pallets and light packaging when shipping in bulk.

- Local Workforce Programs: They support local jobs and training in each country they operate.

- Certifications: Products follow ISO standards for safety and energy performance.

Takeaway Note

Hörmann is best for builders, hotels, and project managers who need consistent supply and strong after-sales support. That said, if your project requires highly customized doors or you’re based outside Europe, expect a longer lead time.

2. Masonite International

Website: https://www.masonite.com

Location: Tampa, Florida, USA

I first worked with Masonite on a multi-unit housing building for a client in Southeast Asia. We needed consistent quality across dozens of doors, and they delivered.

Masonite has been making doors since 1925. They’re one of the longest-standing names in the global door industry. With operations in over 8 countries, they have the capacity and logistics network to handle large-scale projects with ease.

What I liked most was how structured they are. From ordering to delivery, everything moved on schedule. If you’re managing tight deadlines or multiple buildings, that really helps.

Product Range

- Interior Molded Doors: Clean, simple designs made for bedrooms, bathrooms, and hallways. Easy to install and match across multi-room builds.

- Exterior Fiberglass Doors: Weather-resistant and secure. Good for homes and small hotels in humid or coastal regions.

- Steel Doors: Durable and solid. Often used in service areas or for back-of-house access in commercial spaces.

- Wood Doors: Traditional wood grain look. A favorite for upscale residential homes or historic building upgrades.

- Fire-Rated Doors: Compliant with safety codes, ideal for stairwells, corridors, and escape routes in hotels or inns.

Manufacturing Capabilities

Masonite operates more than 60 facilities worldwide. Most of their production is done in-house, including fiberboard, cores, and door assembly.

They offer OEM and support large commercial projects. Their automation systems allow them to produce high volumes quickly while keeping finish consistency across batches.

Their team includes engineers and project consultants, which can be helpful if your build involves code requirements or specific hardware compatibility.

Sustainability & Ethical Practices

- Wood Waste Recycling: They collect sawdust and offcuts from wood doors and reuse them in manufacturing composite cores and particleboard.

- Low-VOC Finishes: Coatings and adhesives used in their doors are low in volatile organic compounds, making them safer for indoor use.

- Energy-Saving Systems: Many plants use automated lighting and energy-efficient motors to reduce electricity consumption across production shifts.

- Water Use Monitoring: Factories are equipped with water recycling units that help reduce water waste during the fiberboard forming process.

- Product Durability Focus: By building long-lasting doors, they help reduce the need for frequent replacements and cut overall material waste over time.

Takeaway Note

Masonite is great for high-volume projects that need reliable supply and strong product variety for both interior and exterior doors. That said, due to their scale, ultra-custom design requests may not get as much personal support as smaller brands.

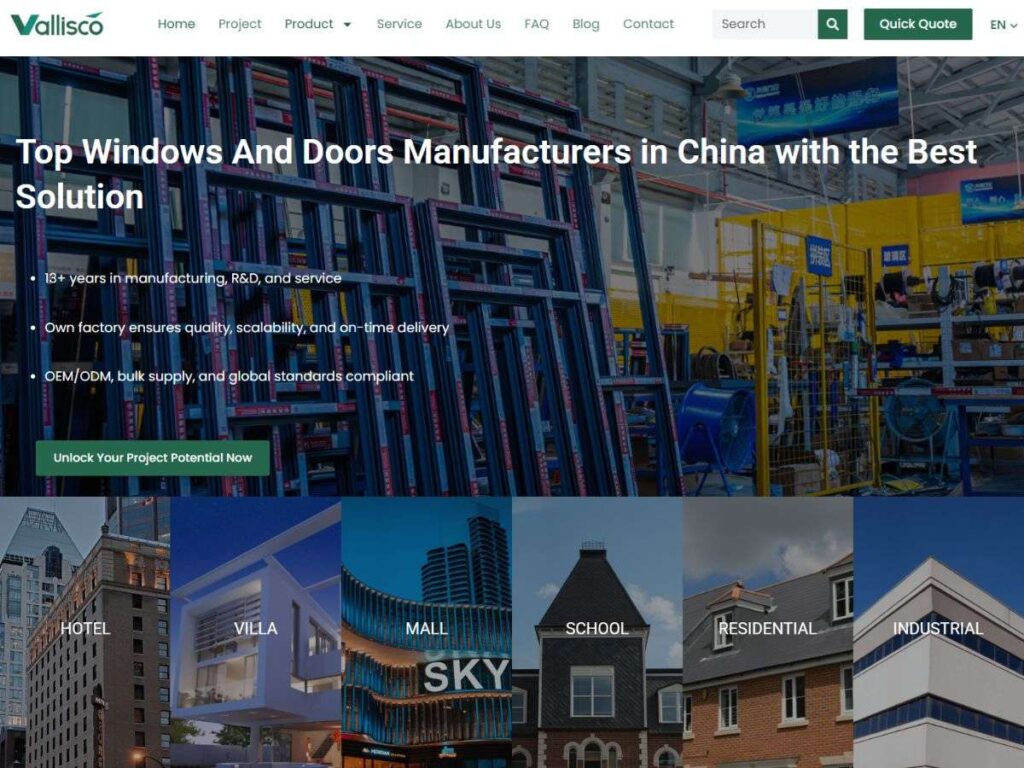

3. Vallisco

Website: https://www.vallisco.com

Location: No. 1926, Cao An Highway, Jiading District, Shanghai, China

I first connected with Vallisco while helping a client source double doors for a villa in Southeast Asia. The project had a tight budget and called for some design flexibility. Vallisco handled both without pushing back.

They’re a newer brand, launched in 2024, but they’re built on over a decade of experience from their parent company in China’s home building market. Their team focuses on working with businesses like you, who handle multiple units, not just one-time orders.

Product Range

- Double Doors: Lightweight, strong, and modern-looking. Ideal for villas, hotel rooms, and small buildings.

- Pivot Doors: Used in entryways or to create open, light-filled spaces in homes and guest areas.

- Garage Doors: Sectional and roll-up options. These are popular in villa and home projects that need weather resistance and automation.

- Sliding Patio Doors: Smooth-sliding, floor-to-ceiling doors. A favorite for poolside units and hotel balconies.

- Frameless Glass Doors: Sleek, minimalist look. Often used in interiors, greenhouses, and boutique spaces.

Manufacturing Capabilities

Vallisco owns a factory in Shanghai. All products are made in-house, which helps with lead time and custom orders. They support OEM and private label. You can customize finishes, dimensions, handles, and even add branding if needed.

Their machines are new, and their setup includes automation for cutting, assembling, and packaging. That’s a plus if you want efficiency without large minimums.

Sustainability & Ethical Practices

- Eco-friendly Materials: Their aluminium and glass come from regional suppliers with environmental certifications.

- Smart Packaging: Orders are packed based on shipping methods and destination to reduce waste.

- Energy-Saving Production: Their factory uses LED lighting and efficient power systems.

- Remote Support: They offer virtual product walkthroughs to reduce travel and on-site visits.

- Ethical Export: Focused on clear invoicing, fair wages, and workplace safety.

Takeaway Note

Vallisco is a good fit for villas, hotels, and multi-unit homes in Southeast Asia or Europe looking for factory-direct support and flexibility.That said, as a newer brand, they’re still building out their reputation and global presence, so you may not find as many past projects or reviews yet.

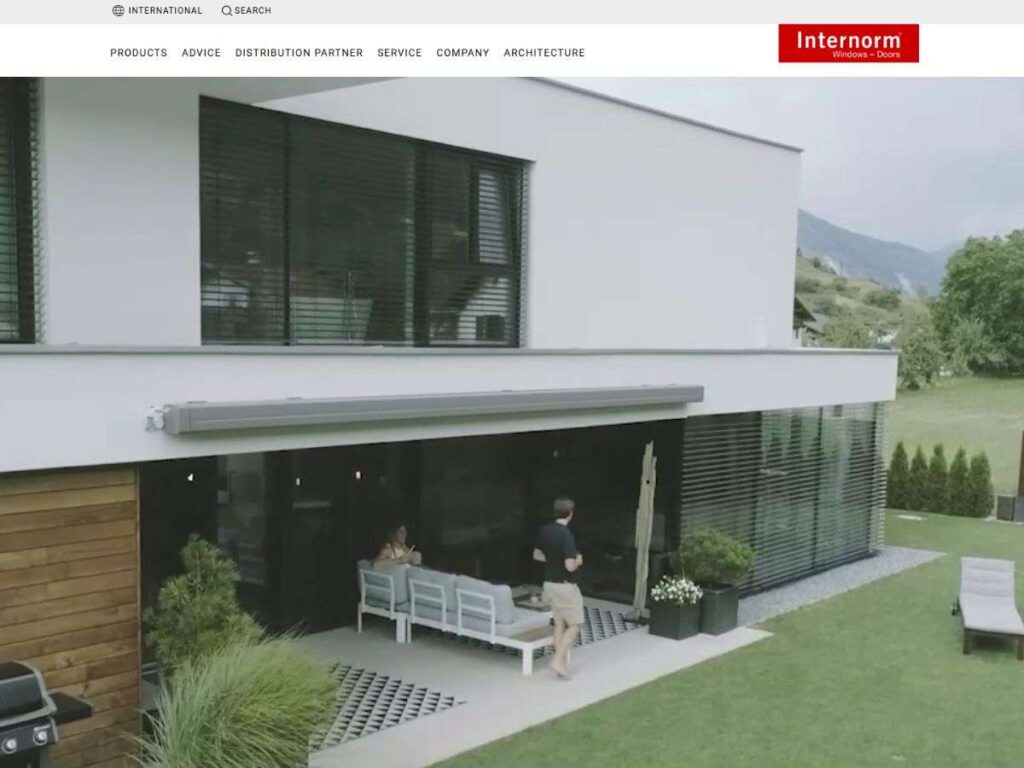

4. Internorm

Website: https://www.internorm.com

Location: Traun, Austria

I first came across Internorm while sourcing high-performance doors for a mountain lodge project in Central Europe. The site needed insulation and strong weather resistance. Internorm delivered both, and the client didn’t need to follow up once.

Internorm has been in the business since 1931. They’re a family-owned Austrian brand with a solid name in energy-efficient doors and windows. Over the years, they’ve built a strong distribution network across Europe.

Product Range

- Aluminium Entrance Doors: Durable and modern. Built with thermal insulation and multi-point locking. Perfect for homes, villas, and inns in colder regions.

- Timber-Aluminium Doors: Wood interior, aluminium exterior. Combines warmth with weather resistance. A strong choice for high-end residential buildings.

- Sliding Glass Doors: Floor-to-ceiling style. These open up views for hotels, villas, or greenhouses.

- Lift-and-Slide Doors: Easy-glide operation. Designed for large openings and energy savings.

- Passive House Doors: Built to meet strict energy standards. Often used in low-energy or sustainable projects.

Manufacturing Capabilities

Internorm runs three plants in Austria and controls every step of the process. Their production includes custom sizing, glazing, and finishes.

They support OEM and project-based customization. Their automation systems help produce high volumes without compromising detail or quality.

Their products are tested under European standards for insulation, wind, rain, and security. That helps if your builds need certifications or technical proof for clients.

Sustainability & Ethical Practices

- Certified Wood Sourcing: Timber comes from controlled forests within the EU.

- Energy-Efficient Products: Most doors meet or exceed passive house standards.

- Factory Waste Recycling: All three plants recycle glass, wood, and aluminium scraps.

- Low-Impact Finishes: Their paints and coatings are solvent-free and safe for indoor use.

- Community Training: Runs apprenticeship and local hiring programs in Austria.

Takeaway Note

Internorm works well for hospitality and residential projects where energy performance and long-term durability matter most. However, since they focus on Europe, shipping outside the region may cost more and take longer to coordinate.

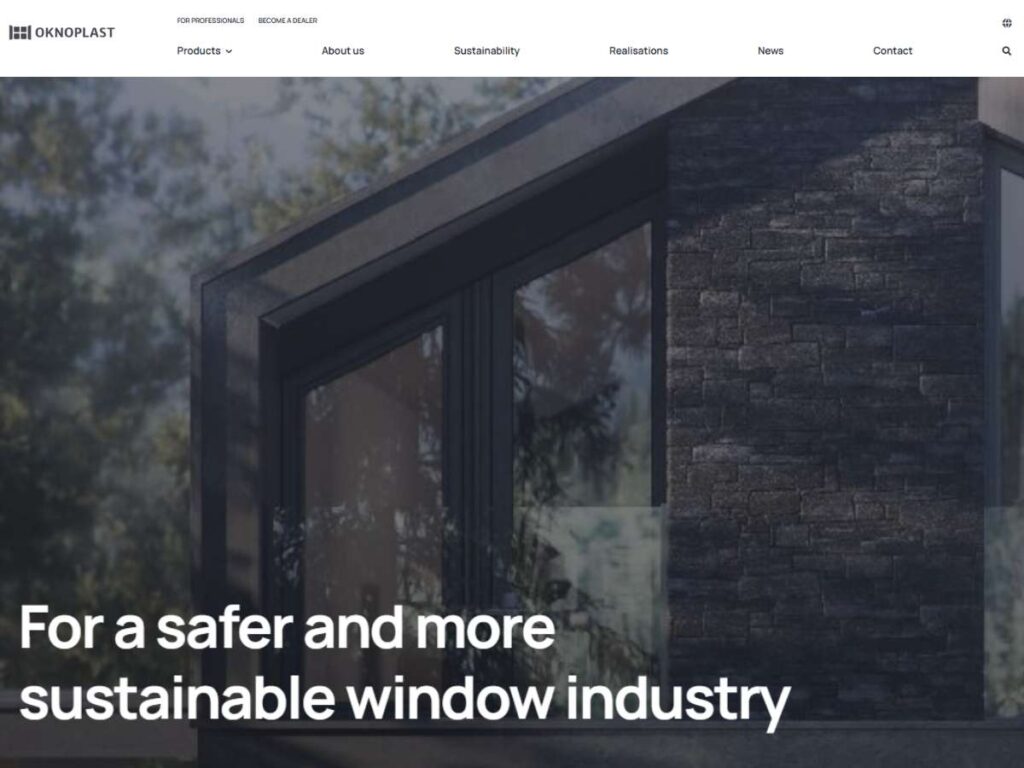

5. Oknoplast

Website: https://www.oknoplast.com

Location: Ochmanów, near Kraków, Poland

I first looked into Oknoplast while helping a client retrofit a B&B in southern France. They wanted quality doors without long lead times. Oknoplast had inventory nearby, and delivery was fast.

The company started in 1994 and has grown into one of Europe’s well-known window and door brands. They serve over a dozen countries and operate with over 3,500 partner showrooms across Europe.

Product Range

- PVC Double Doors: Low maintenance and weather-resistant. A practical choice for houses and mid-range hotel renovations.

- Aluminium Doors: Strong and slim-profiled. Often used for upscale villas or modern B&Bs that want clean lines.

- Sliding Doors: Space-saving and stylish. Good for pool areas, patios, and balconies.

- Entry Doors: Insulated and secure. Designed to block sound and hold up against daily wear in busy homes or inns.

- French-Style Doors: Classic design with updated materials. Works well in traditional homes or boutique accommodations.

Manufacturing Capabilities

Oknoplast operates a 32,000 m² facility near Kraków. They build most of their doors and windows in-house and have systems for quality control at each step.

They offer custom colors, finishes, and glass options. OEM and ODM are supported, especially for large project orders.

Their factory uses modern production lines and digital tools to reduce errors and speed up production. That helps if you’re managing tight project deadlines.

Sustainability & Ethical Practices

- PVC Recycling: They collect and reuse old PVC frames and offcuts during production to cut down plastic waste and reduce landfill impact.

- Energy-Efficient Profiles: Most doors are built with thermal barriers to reduce heat loss and meet strict energy codes in Europe.

- Solar-Powered Lighting: Parts of their factory use solar panels and LED lighting to lower electricity use during day and night shifts.

- Water Recycling System: They filter and reuse water used in cooling and cleaning processes, which saves water across the production cycle.

- Local Job Creation: They train and hire from the surrounding region to keep economic support within their local communities.

Takeaway Note

Oknoplast is a smart pick for European projects needing energy-efficient doors, fast delivery, and clean styles. That said, if you’re ordering from outside Europe, shipping arrangements may require extra coordination or a regional partner.

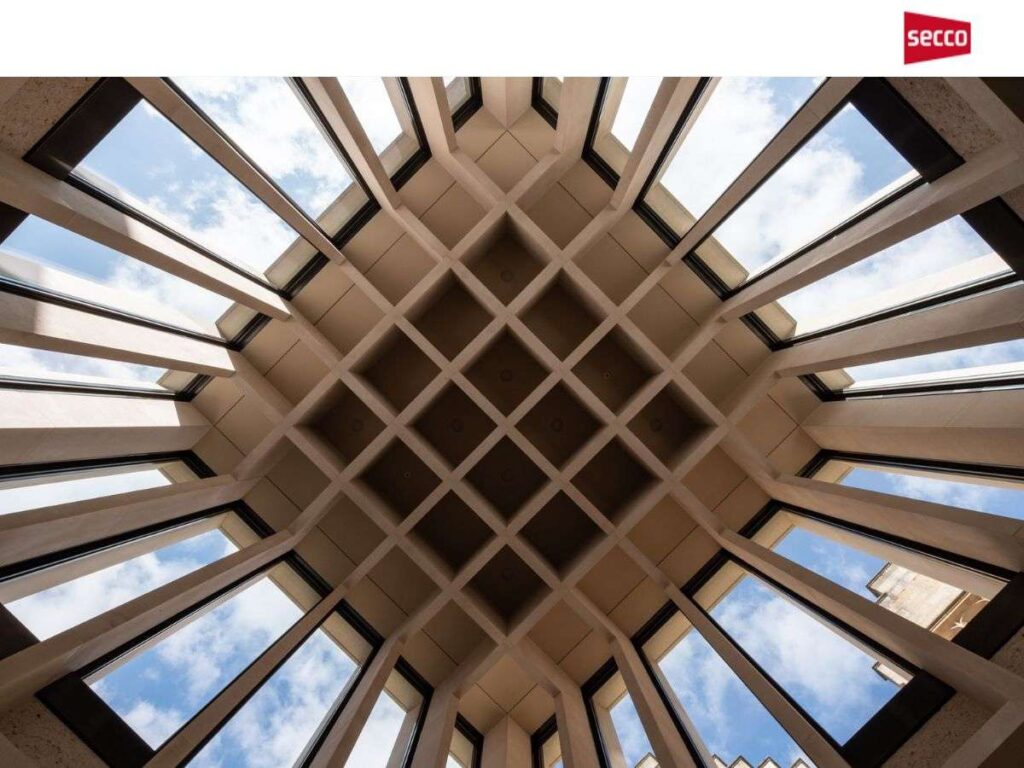

6. Secco Sistemi

Website: https://www.seccosistemi.com

Location: Preganziol, Treviso, Italy

I first found Secco Sistemi through an architect on a boutique hotel project in Milan. The client wanted doors that looked custom but performed like commercial ones. Secco checked both boxes.

Founded in 1947, Secco is an Italian brand known for high-design door and window systems. They work closely with architects, builders, and contractors on buildings that call for clean finishes and long-lasting materials.

Product Range

- Bronze-Framed Doors: Warm-toned, corrosion-resistant doors made for upscale homes or hotels. Great for seaside or urban spaces needing premium finishes.

- Galvanized Steel Doors: Strong and secure, yet slim. Used for entries and transitional spaces in high-traffic or commercial properties.

- Corten Steel Doors: Rusted look that ages naturally. Often seen in modern villas and design-led hospitality buildings.

- Stainless Steel Doors: Sleek and polished. A popular choice in modern buildings with minimalist themes or exposed materials.

- Thermal Break Doors: Built with insulation layers to stop heat or cold from transferring between inside and out.

Manufacturing Capabilities

Secco runs production in Italy and builds almost every part in-house. Their machines are made for high-precision cutting and joining metal frames.

They support full project customization. Whether you’re matching historical doors or planning modern frames, they handle drawings, finishes, and glass types.

Their team is experienced with complex orders and works closely with site engineers to support smooth installations.

Sustainability & Ethical Practices

- Recycled Materials: They use recycled metals like bronze, steel, and aluminium to reduce raw material use and support closed-loop production.

- Low-Energy Finishing: Their metal finishing process uses minimal electricity and avoids harmful chemicals common in large-scale coating systems.

- Waste Collection: Leftover metal and offcuts are sorted by type and sent to recycling facilities to avoid unnecessary waste and disposal.

- Energy-Conscious Operations: Factory equipment is optimized to run at lower temperatures and reduces energy during off-peak hours.

- Design Longevity: Their products are built to last decades, which lowers replacement rates and overall impact on long-term building waste.

Takeaway Note

Secco Sistemi fits well with design-heavy projects like villas, boutique hotels, or luxury homes that need long-lasting, detailed finishes. However, since their focus is on custom design, lead times can be longer, especially during high-volume seasons.

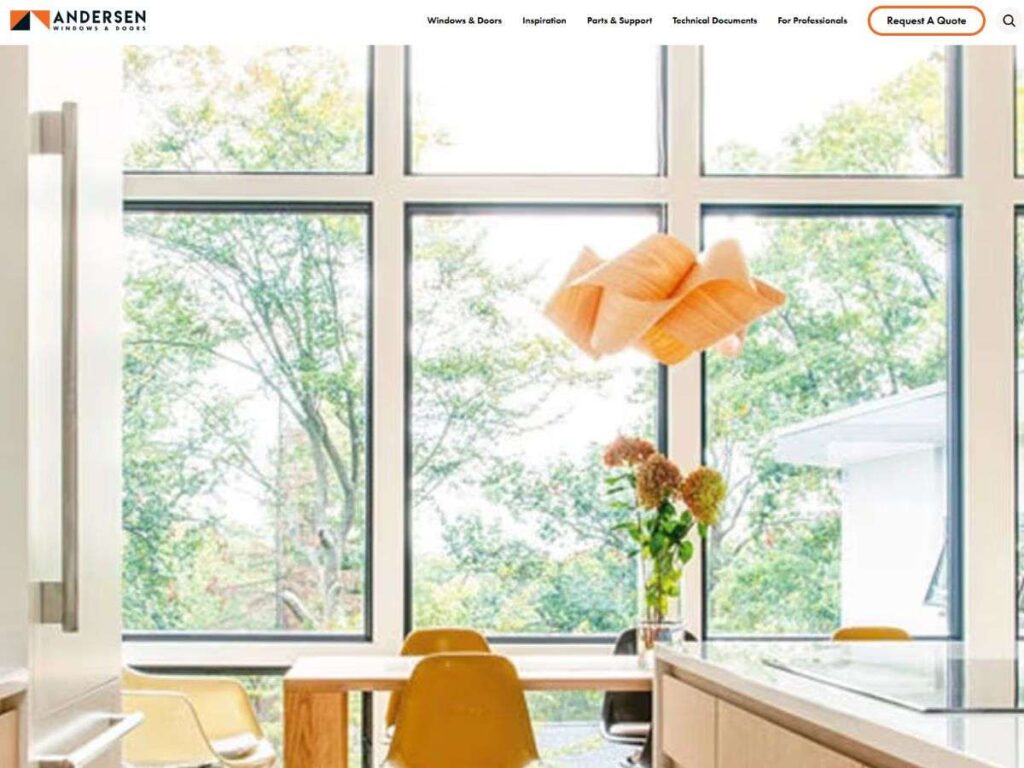

7. Andersen Corporation

Website: https://www.andersenwindows.com

Location: Bayport, Minnesota, USA

I first explored Andersen’s product line while working on a resort project in Northern Europe. The property needed patio doors that could handle both cold and coastal weather. Andersen had options ready.

Founded in 1903, Andersen is one of the oldest door and window companies in the U.S. They have a global footprint and are especially known for their energy-efficient glass and frame systems.

Product Range

- Sliding Patio Doors: Made for larger openings. Great for guesthouses, villas, or rooms that open into gardens or pools.

- French Doors: Classic double doors with updated materials. Often used in high-end homes and boutique hotel entrances.

- Gliding Doors: Smooth operation, ideal for tight spaces where swing doors won’t work.

- Hinged Entry Doors: Durable and energy-conscious. These are suitable for homes and guest rooms that face changing outdoor climates.

- Commercial-Grade Doors: Designed to meet fire codes and building regulations. Used in larger developments or high-occupancy units.

Manufacturing Capabilities

Andersen runs several factories across North America. They manufacture wood, composite, and fiberglass products in-house, including their own materials like Fibrex®.

They support OEM, and many doors can be adjusted for custom sizes, finishes, or glass. Their technology includes digital planning tools and automated machinery to support large orders.

Their factory teams are trained to work on residential and commercial batches side by side, which helps reduce production delays.

Sustainability & Ethical Practices

- Reclaimed Wood Use: Many wood doors use FSC-certified or reclaimed wood to reduce reliance on new forestry and help protect old-growth forests.

- Fibrex® Composite Innovation: Their proprietary material combines recycled wood fiber and polymers to lower waste and improve long-term energy performance.

- Energy Star Certified: Most products meet or exceed Energy Star standards, which means lower heating and cooling needs in finished buildings.

- Waste Reduction in Plants: Andersen reports recycling over 90% of manufacturing waste through dedicated sorting and material recovery systems.

- Community Investment: They support skilled trades education, disaster relief, and workforce development programs in local U.S. communities.

Takeaway Note

Andersen is a strong fit for builders working on energy-conscious villas, hotels, or high-end homes that need dependable quality and support. That said, lead times can be longer during peak demand, especially for complex finishes or special glass configurations.

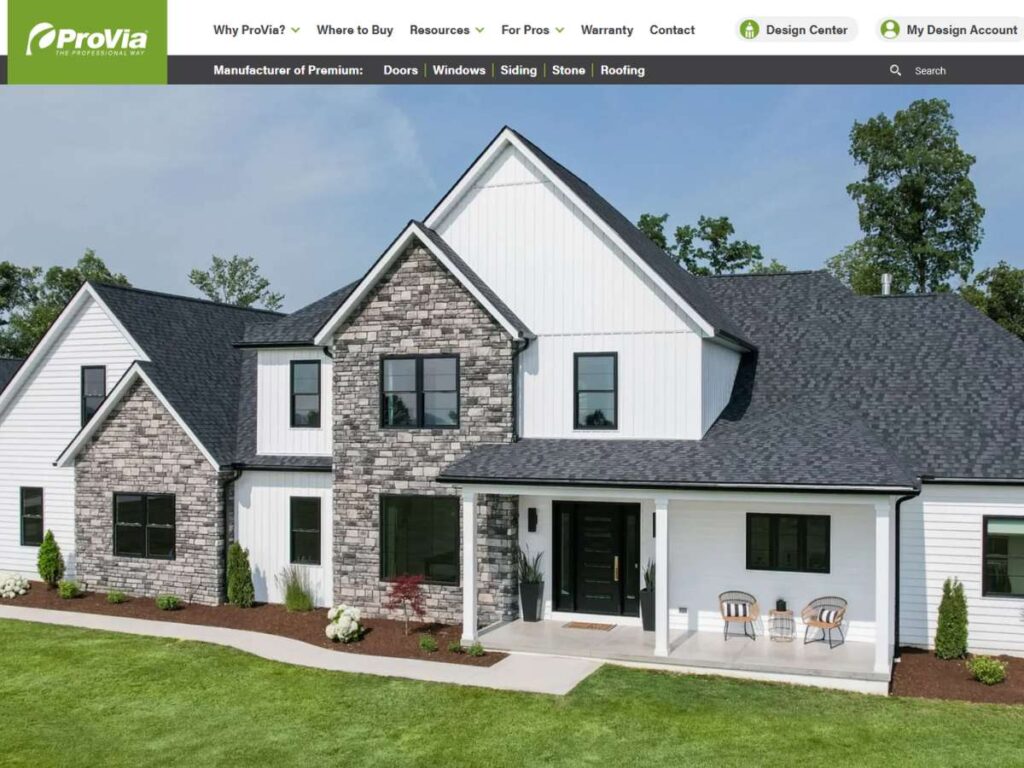

8. ProVia

Website: https://www.provia.com

Location: Sugarcreek, Ohio, USA

I came across ProVia while working with a villa owner in a colder climate. They wanted doors that looked clean but also sealed tight. ProVia’s fiberglass options were a perfect match.

ProVia began in the 1970s and has grown steadily in the U.S. market. They’re known for combining craftsman-style design with energy-efficient technology. Though smaller than some manufacturers, their focus is quality over mass production.

Product Range

- Fiberglass Entry Doors: Durable, insulated, and available in smooth or woodgrain textures. A go-to for homes and villas in variable climates.

- Steel Security Doors: Built for safety and strength. Good for side entrances or utility areas in guesthouses or B&Bs.

- French Patio Doors: Classic look with modern insulation and locking systems. Often used to connect indoor spaces to outdoor patios or gardens.

- Gliding Doors: Space-saving and secure. Suitable for compact units or guest rooms with balcony access.

- Storm Doors: Extra layer of weather protection. Used in climates with strong wind, rain, or snow.

Manufacturing Capabilities

ProVia runs production from its facilities in Ohio. All doors are manufactured in-house, with a focus on craftsmanship and consistency.

They offer OEM and private label services, especially for regional builders. Custom options include size, color, glass type, hardware, and finishes.

Though not a high-volume producer like others, ProVia is known for low defect rates and on-time delivery, especially in the North American market.

Sustainability & Ethical Practices

- Energy-Efficient Cores: Their doors use foam-filled cores that increase insulation and help reduce long-term heating and cooling costs in buildings.

- Recycled Materials: They incorporate recycled steel and fiberglass content to reduce raw material consumption in their standard door lines.

- Green Building Certifications: Many of their products meet LEED requirements, helping your projects earn points for sustainability credits.

- Lean Manufacturing: They follow lean processes to limit excess inventory and reduce material waste during production runs.

- Workplace Ethics: Based in a small community, they prioritize worker safety, fair wages, and family-first employment policies.

Takeaway Note

ProVia works well for clients needing solid, energy-conscious doors with good service and delivery across North America. That said, their smaller scale means longer lead times for large international orders or high customization needs.

Conclusion

You saw the challenge I faced early on, finding the right door supplier. I fixed that problem by doing the homework. And we’ve just shared that with you.

This guide is built to save you time, money, and stress. It connects you with manufacturers that fit real-world builds, not just catalogs.

Whether you’re building up or renovating, the right door partner can make all the difference.

If you need support that’s grounded and flexible, Vallisco works well for villa and hotel builds.

Contact us today and let’s get your project moving in the right direction.

Explore Related Resources

Want to see more? We’ve gathered additional product choices to give you even more variety:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.