A villa contractor once told me he bought machines he never used, while missing the ones he needed most. He learned the hard way that choosing the wrong equipment hurts both budget and deadlines.

His story is not rare. Many house builders, hotel teams, and workshop owners face the same challenge when setting up production.

I work closely with businesses who need doors and windows for larger projects. With years of practice, I know which machines are practical and which are not worth the investment.

This article will give you a breakdown of the essential security door manufacturing equipment. Each section explains what the machine does and why it matters for your work.

The right knowledge helps you avoid wasted money and wasted effort.

Let’s get started!

Quick Comparison Chart

Choosing the right machines is easier when you can compare them side by side. Below is a simple table that shows the main role, cost level, and other key points of each machine group. This gives you a quick overview before reading the details.

| Machine Type | Main Function | Scale of Use | Cost Level | Impact on Quality | Maintenance Needs | Best For |

| Sheet Metal Cutting Machines | Cut steel sheets into panels/frames | Small to large shops | Medium-High | High – precision fit | Moderate (laser/plasma need care) | Businesses producing custom or large volume doors |

| Bending & Forming Machines | Shape sheets into frames, panels | Small to large shops | Medium | High – strength & fit | Low-Moderate | Workshops making frames or structural parts |

| Welding & Assembling Machines | Join parts into one structure | Medium to large shops | Medium-High | Very High – structural strength | Moderate | Factories making high-security or heavy doors |

| Surface Treatment & Finishing Machines | Coating, polishing, rust protection | Medium to large shops | High | High – durability & look | Moderate-High | Businesses needing long-lasting, rust-free doors |

| Lockset & Hardware Installation Machines | Drill/punch for locks, hinges | Small to large shops | Medium | High – smooth fitting | Low | Workshops focused on hardware-ready doors |

| Insulation & Filling Machines | Fill doors with foam or core | Medium to large shops | Medium | Medium – energy/sound performance | Low | Factories adding thermal and soundproof doors |

| Quality Control & Testing Equipment | Test strength, fire, security | Larger factories | Medium | Very High – safety standards | Low | Businesses needing certified security doors |

This table gives you a quick snapshot of each machine group and how they fit into security door production. Read more below for a full breakdown of each one.

1. Sheet Metal Cutting Machines

Cutting is the first step in making a strong security door. I’ve seen many workshops struggle because their cutting machines were either too basic or too advanced for their needs. If you choose the right one, you save time, money, and avoid mistakes down the line.

Laser Cutting Machines

- High Precision: Laser machines cut with very fine accuracy, which means cleaner edges and better fitting parts. This reduces extra grinding or correction work later.

- Good for Custom Designs: If you work with villas, hotels, or houses that want specific patterns, a laser cutter handles it with ease. It gives you flexibility for both plain and decorative panels.

- Higher Cost Investment: The upfront cost is higher compared to other machines. But many businesses find it worth it because accuracy lowers waste and speeds up production.

- Works Best for Steel Sheets: Most security doors use steel panels. A laser cutter handles these materials well, even with thicker gauges.

Shearing Machines

- Fast and Simple Cuts: Shearing machines are practical when you need to cut large numbers of sheets quickly. They work best for straight lines and standard-sized panels.

- Lower Cost Option: They cost less than laser or plasma machines, which makes them a good entry choice if you are starting small.

- Less Flexible for Complex Designs: If your clients ask for custom patterns, a shear will not cover that. It is mainly for plain cuts.

- Durable and Reliable: With basic care, shearing machines last a long time. Many smaller workshops still depend on them every day.

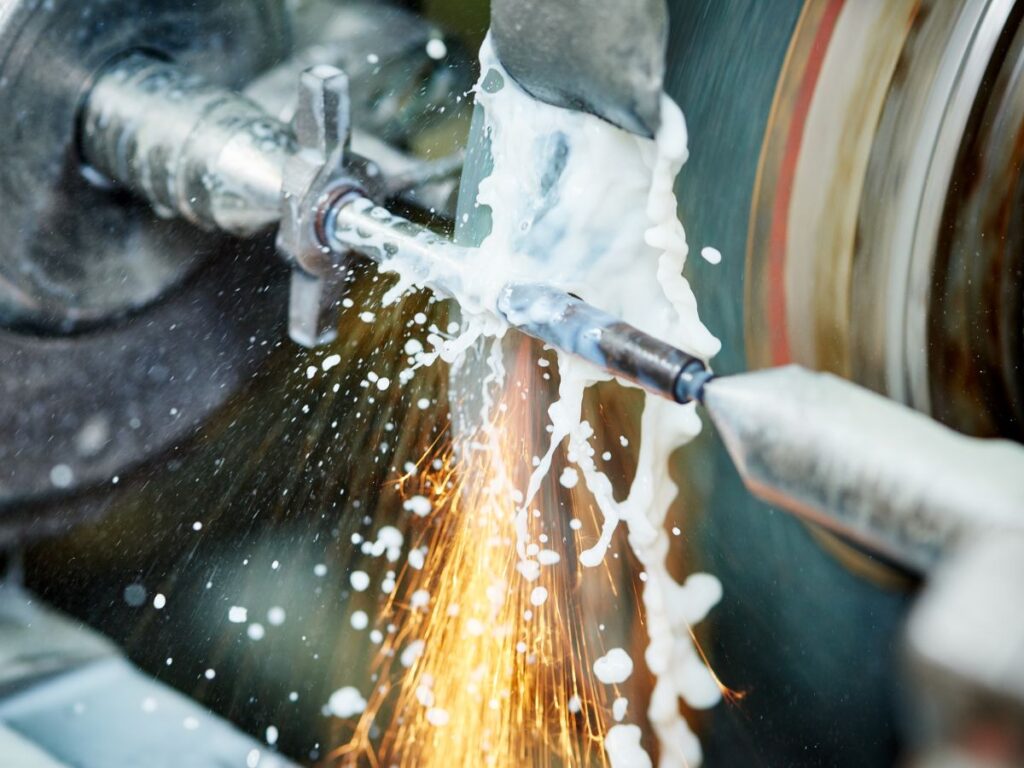

Plasma Cutting Machines

- Good for Thick Materials: Plasma cutters handle heavy steel sheets that other machines might struggle with. This makes them useful for high-security doors.

- Lower Upfront Cost Than Laser: They are less expensive than laser machines but still offer faster and cleaner cuts than manual methods.

- Edge Quality Not as Smooth: Plasma cuts are not as clean as laser, so you may need extra grinding or polishing. This adds a step in your workflow.

- Strong for Heavy-Duty Work: If you work with industrial or large-scale projects, a plasma cutter can handle the demand better than a shear.

2. Bending & Forming Machines

After cutting comes bending, and this step decides how well the door frame and panels hold their shape. I’ve visited workshops where the wrong bending setup slowed everything down and caused weak frames.

If you get this step right, your doors come out stronger and fit better. Vallisco, a well-known manufacturer of security doors, relies heavily on proper bending machines to keep their production consistent and efficient.

Press Brake Machines

- Accurate Bending: A press brake bends sheet metal into frames and door skins. This makes sure the panels line up the way they should during assembly. Without it, frames can warp and cause problems later.

- CNC Options for Precision: CNC press brakes help with complex bends and reduce mistakes. CNC bending is used for many of their projects because it keeps every piece the same size and angle.

- Good for Different Materials: Whether you use steel, aluminum, or other metals, a press brake handles them well. That’s why many factories keep one as their main bending tool.

- Different Sizes Available: Small workshops can use manual or semi-automatic types, while large operations often invest in bigger hydraulic models for faster output.

Roll Forming Machines

- Continuous Profiles: Roll forming machines shape long strips of steel into profiles for door frames and reinforcements. This process is fast and steady, which makes it ideal for bigger projects.

- High Volume Production: If you need to supply large orders, roll forming speeds up the job. Each pass through the rollers comes out identical.

- Less Waste: Because the machine forms material as it goes, there is less scrap compared to cutting and bending each piece separately. That can save you money on materials over time.

- Best for Large Factories: Smaller workshops may find it too big an investment, but for larger-scale production, it quickly pays back the cost.

Hydraulic Folding Machines

- Simple to Operate: Hydraulic folding machines are easier for workers to learn compared to CNC press brakes. They suit smaller factories or teams that want a flexible machine without much training.

- Good for Standard Doors: Many standard-sized doors can be shaped with hydraulic folders. If you are not handling complex bends, this machine covers most needs.

- Lower Investment Cost: The price is usually less than a CNC press brake, which makes it practical for growing businesses.

- Less Precision Than CNC: While reliable, the bend accuracy may not match CNC systems. If you want every door perfectly identical, this may require extra checks.

Combination Use in Production

- Press Brake for Frames, Roll Forming for Profiles: Many businesses use both machines side by side. Frames are bent on press brakes, while profiles and long strips are shaped on roll formers.

- Flexibility in Workflow: Using a mix of machines lets you cover both small custom orders and big runs at the same time.

- Scalable Setup: Starting with one press brake is enough for many workshops. As you grow, adding a roll former or hydraulic folder gives you more output and flexibility.

3. Welding & Assembling Machines

After bending, the next stage is joining all the parts together. I’ve been inside factories where poor welding created weak spots, and the doors failed basic strength tests. You don’t want that happening in your production. Good welding and careful assembly make the difference between a door that lasts and one that needs repair too soon.

Spot Welding Machines

- Fast Joining for Sheets: Spot welding connects two steel sheets at specific points. This method is quick and common for door skins.

- Strong Enough for Layers: A good spot weld holds the layers tight so they don’t shift over time. If you’re making high-security doors, this step is critical.

- Affordable Equipment: Spot welders cost less than large MIG or TIG systems. Many workshops use them as a base machine.

- Ideal for Thin Steel: These machines work best on thinner panels. For thicker parts, you’ll need additional welding methods.

MIG and TIG Welding Machines

- Reliable Frame Welding: MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding are common for door frames and hinges. Both give stronger joints compared to spot welding.

- MIG for Speed, TIG for Precision: MIG is faster and suits larger production. TIG is slower but more accurate, often used where appearance matters.

- Versatile Use: These machines handle different thicknesses of steel. That makes them practical for mixed production needs.

- Skilled Operators Needed: Workers need training to get consistent results. Without it, welds can weaken the frame.

Automatic Welding Robots

- Boosts Productivity: In larger factories, robotic welding speeds up the process. Each weld is done the same way, reducing variation.

- Good for High Volume: If you handle contracts for hotels, apartments, or large housing projects, robots help you meet deadlines.

- High Initial Cost: The investment is significant, so it makes sense only if your production scale is big.

- Less Human Error: Since the machine repeats the process, there’s less chance of mistakes compared to manual welding.

4. Surface Treatment & Finishing Machines

A good security door is more than just strong metal. If the surface is left untreated, it rusts, fades, and wears down faster. I’ve seen businesses lose contracts because their doors didn’t look professional enough after a few years of use.

Companies like Vallisco, who manufacture security doors at scale, treat finishing as a priority, because it protects the product and builds customer trust.

Powder Coating Lines

- Rust and Corrosion Protection: Powder coating covers the metal with a dry layer that resists moisture. For doors used in humid climates like Southeast Asia, this step is critical.

- Better Appearance: Powder coating gives a smooth, even finish. It is used to meet both security and design expectations for hotels and villas.

- Eco-Friendly Process: Unlike wet painting, powder coating has fewer emissions and is cleaner for workers. Many clients appreciate this factor.

- Higher Initial Cost: Setting up a coating line requires space and investment. It pays back when you produce at medium or large volumes.

Polishing and Grinding Machines

- Smooths Edges: Grinding removes sharp or rough edges after cutting and welding. This keeps workers safe and prepares the door for coating.

- Improves Look: Polished surfaces give doors a professional appearance. Customers in Europe, for example, often demand a clean finish.

- Essential for Quality Control: Without polishing, paint and coating may not stick evenly. That creates weak spots.

- Low to Medium Investment: Smaller machines are affordable and easy to add even in modest workshops.

Sandblasting Equipment

- Prepares Surfaces for Coating: Sandblasting cleans the metal by removing scale, rust, or leftover weld marks. A clean base makes powder coating last longer.

- Improves Durability: Doors that are sandblasted before coating resist scratches and peeling better. Some include this step for doors supplied to coastal areas.

- Different Media Choices: You can use sand, beads, or other materials depending on your finish needs. This gives flexibility for different clients.

- Moderate Cost: Sandblasting setups vary in price. Portable units are cheaper, while full booths suit larger production lines.

Optional Wet Painting Systems

- Lower Startup Cost: Wet painting is cheaper to set up than powder coating. Some smaller workshops still use it for budget-conscious projects.

- Less Durable Than Powder: Wet paint doesn’t last as long, especially in humid or outdoor conditions.

- Color Flexibility: It allows more shades and finishes, which can be useful if a client requests special designs.

- More Maintenance: Wet painting requires careful handling of fumes and waste. That adds to operational work.

5. Lockset & Hardware Installation Machines

A strong door still needs the right lock, hinges, and hardware to make it complete. I’ve seen projects delayed because teams had to manually drill or adjust holes that didn’t line up properly. With the right machines, you avoid wasted time and make sure every lockset works smoothly once installed.

CNC Drilling and Milling Machines

- Precise Openings for Locks: CNC drilling creates exact holes for lock cylinders, handles, and peepholes. This precision avoids alignment issues that can cause locks to jam.

- Good for Custom Orders: If your client wants different lock systems, CNC gives you the flexibility to match each requirement. That’s important in projects for villas or hotels where each door may vary.

- Higher Skill Level Needed: Operators must know how to program and adjust the CNC machine. With training, it saves hours compared to manual drilling.

- Trusted by Larger Producers: Many established factories rely on CNC milling because it keeps every door consistent across big batches.

Punching Machines

- Fast for Hinges and Plates: Punching machines quickly stamp holes or slots where hinges and lock plates will be attached. This speeds up hardware fitting.

- Efficient for Large Runs: If you’re producing hundreds of doors, punching is much faster than drilling each hole by hand.

- Lower Cost Than CNC: Punching machines are generally more affordable. They are a good option for medium-sized workshops.

- Limited Flexibility: While quick, punching machines are less flexible when it comes to non-standard hardware or new designs.

6. Insulation & Filling Machines

A door’s strength is important, but insulation is what makes it practical for real use. I’ve worked with clients who wanted quieter rooms or better temperature control, and the filling process was the key factor. If you use the right machines here, you give your customers security and comfort in one product.

Foam Injection Machines

- Thermal and Sound Control: Foam injection fills the space inside the door with polyurethane foam. This helps keep heat out in summer and noise down in busy areas.

- Adds Structural Support: The foam gives extra stiffness to the door panel, making it harder to bend or break. This is useful for villas and hotels where durability matters.

- Fast Process: Modern machines can inject foam in seconds, which speeds up production lines. That’s a big advantage if you handle large orders.

- Low Operating Cost: Once set up, foam machines are simple to run and require little upkeep compared to other heavy equipment.

Honeycomb Core Filling Equipment

- Impact Resistance: Honeycomb paper or steel cores add strength to the door without making it too heavy. This makes them popular in projects that need high security.

- Cost-Effective Option: Paper honeycomb is cheaper than steel cores. Businesses often choose it for mid-range projects where cost control is important.

- Flexible Production: The machine allows you to switch between different core types depending on the order. That helps when your clients want different door levels.

- Preferred for Fire-Rated Doors: Steel honeycomb cores are often used in fire-rated security doors, especially for hotels and public buildings.

Mineral Wool Filling Systems

- Fire Resistance: Mineral wool is an excellent insulator against heat. Doors filled with it provide extra safety in case of fire.

- Good for Noise Control: It blocks sound well, making it ideal for B&Bs or urban houses where noise is an issue.

- Higher Material Cost: Mineral wool costs more than foam or paper honeycomb. Businesses often use it only for special projects.

- Special Handling Needed: Workers must take care during filling since mineral wool can irritate skin. Machines designed for safe handling make the job easier.

7. Quality Control & Testing Equipment

A door may look finished, but without testing, you never really know if it can perform under pressure. I’ve met clients who thought their products were ready until testing showed weak spots. That experience taught me one thing: testing equipment protects your reputation as much as it protects the buyer.

Universal Testing Machines (UTM)

- Checks Door Strength: A UTM applies force to see how much weight or pressure the door can take before bending or breaking. This proves your product can handle real use.

- Key for Heavy-Duty Projects: In hotels or public buildings, buyers expect doors that last. Strength tests give you the data you need to win those contracts.

- Records Data for Standards: UTMs provide measurable results you can present during inspections or certifications. That builds trust with engineers and buyers.

- Medium to High Cost: The machines are an investment, but many factories find them necessary for maintaining consistent quality.

Fire Resistance Testing Equipment

- Simulates Fire Conditions: These machines expose doors to controlled fire and heat. The goal is to check how long the door can hold before failure.

- Important for Regulations: Hotels, apartments, and public buildings often require certified fire doors. Without proper testing, your doors may not pass approval.

- High Trust Factor: Showing clients that your doors have been tested for fire resistance is a strong selling point in B2B projects.

- Specialized Setup: Fire testing equipment requires trained staff and safety systems, so it’s often used by larger factories or third-party labs.

8. Factors to Consider When Choosing the Right Machines

I’ve talked with many business owners who rushed into buying equipment and later regretted it. Some machines sat unused, while others couldn’t handle the jobs they were bought for. If you think carefully about your situation before investing, you’ll save both money and stress.

- Production Scale: Ask yourself how many doors you need to make each week or month. A small workshop doesn’t need the same setup as a factory supplying hotels or housing projects. Starting with the basics and adding machines as you grow is often the smarter move.

- Budget and ROI: Machines come at different price points, and the cheapest isn’t always the best fit. Look at how quickly each machine will pay itself back through saved labor or faster production. That way, your purchase is an investment, not just a cost.

- Supplier Support: A reliable supplier matters as much as the machine itself. Make sure spare parts, training, and service are available in your region. If a breakdown stops your production for weeks, the lost business will hurt more than the repair bill.

- Future Needs: Think beyond today’s orders. Will your clients start asking for fire-rated doors, soundproof models, or higher volumes? Choosing machines that can adapt to future projects keeps your workshop ready without another big investment right away.

Conclusion

That villa contractor I mentioned at the start? He later told me that once he invested in the right machines, his production ran smoother and his projects finished faster.

The same can be true for you. From cutting and bending to filling and testing, every step depends on choosing the right equipment.

This guide walked you through the essentials, and now the choice is in your hands.

If you’re ready to make stronger, better doors that meet client demands, don’t wait. Contact Vallisco today and get expert support for your security door manufacturing needs.

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.