We once had a client lose a booking because the front door arrived scratched and 2 weeks late. If you’ve been in a similar spot, you know that one bad supplier can create a chain of headaches.

That’s why picking the right front door manufacturer is important. You need someone reliable, who understands projects like yours.

This review comes from our direct work with builders, property owners, and developers. We’ve tested several suppliers and looked at the things that matter most, product consistency, support, and lead time.

You’ll find 8 front door manufacturers in this article. If you’re sourcing for hotels, villas, or homes, you’ll find useful comparisons to help you decide faster.

The right doors protect more than entry. They protect your timeline and your reputation.

Let’s dive in!

Quick Comparison Chart

Choosing the right front door manufacturer depends on your project size, quality expectations, and level of customization needed. Below is a comparison table to help guide your selection:

| Manufacturer | Product Focus | Customization | Volume Capacity | Support System | Best For |

| Marvin | Wood, steel, fiberglass doors | Moderate (OEM) | Very high | Global, structured | Large-scale housing, resorts, mixed builds |

| Hörmann | Steel, timber, security doors | Moderate (OEM) | High | Europe-wide network | Hotels, villas, fire/security builds |

| Vallisco | Aluminum, steel, glass doors | High (OEM, ODM) | Medium-high | Direct factory team | Villas, hotels, mid-size custom projects |

| Internorm | Timber-aluminum, passive doors | High (OEM) | High | Dealer-led in EU | Passive homes, luxury villas, EU projects |

| Andersen | Wood, fiberglass, smart doors | High (OEM) | Very high | Global, strong | Hotels, upscale homes, tech-focused builds |

| Masonite | Wood, composite, steel doors | Moderate (OEM) | Very high | Distributors + direct | Mass housing, chain hotels, urban blocks |

| Pella | Wood, fiberglass, premium doors | High (OEM) | High | U.S. regional dealers | Premium homes, boutique hotels, villas |

| Therma-Tru | Fiberglass, steel, prehung doors | Moderate (some OEM) | High | U.S. support teams | Moisture-prone sites, fast installs |

Use this table as a starting point to narrow down manufacturers that fit your project goals. Read more for deeper insights into each brand.

1. Marvin

Website: https://www.marvin.com/

Location: Warroad, MN

Email: 1-888-262-4192

Marvin has been making doors since 1960. I’ve worked with their products on a few hospitality projects, and they’ve been consistent, both in quality and delivery. They’re one of the bigger names out there, with factories across North America, Europe, and Australia.

If you’re looking to place bulk orders and need someone who knows how to manage volume without cutting corners, they’re a strong option. They also own several brands under their group, so you get access to a wide variety of looks and features.

Product Range

- Fiberglass entry doors

- Steel front doors

- Wood panel doors

- Glass-integrated doors

- Fire-rated exterior doors

- Prehung door systems

Quality Control & Assurance

- Material sourcing: Materials are sourced from vetted suppliers. They use FSC-certified wood where required.

- Standards followed: Doors meet North American and EU safety codes.

- In-house testing: Each plant includes product testing for durability, weather resistance, and seal strength.

- Third-party audits: Routine quality audits are done across major factories.

- Customer handling: From what I’ve seen, Marvin resolves claims fairly quickly. You get support when things go wrong.

Manufacturing Capabilities

- Capacity: High-volume production, suitable for hotel chains and residential developers.

- Customization: OEM, private label, and custom sizing available for most lines.

- Automation: Large plants use modern automation for consistency in cutting, assembly, and finishing.

- Production model: Most manufacturing is done in-house with regional supply centers for faster fulfillment.

Takeaway Note

Marvin works best if you need a large supplier with steady quality. Ideal for hotels, townhouses, and bulk home builds. Drawback? Less flexible on low-volume, highly custom projects. But for most builders and developers, they’re a dependable go-to.

2. Hörmann

Website: www.hoermann.com

Location: Germany

Email/Phone: info@hoermann.com / +49-5204-9150

Hörmann is one of the oldest door manufacturers still running today. They started in 1935 and have stayed family-owned since. I first came across their doors in a hospitality building in central Europe. What stood out was how solid the construction was, especially their steel units.

They’ve grown into a global company with over 6,000 employees and more than 25 plants. If you’re sourcing doors for buildings that need a solid look and long lifespan, think hotels or villas in high-traffic areas, this is a brand to consider.

Product Range

- Timber front doors

- Aluminum entrance doors

- Fire and smoke-proof doors

- Acoustic-rated doors

- Automatic door systems

Quality Control & Assurance

- Sourcing: Uses German and European steel and timber. All traceable.

- Manufacturing standards: All products meet EU safety and energy codes.

- Testing: In-house labs check for strength, fire resistance, and insulation.

- Certifications: Products carry CE marks, ISO standards, and energy labels.

- Support: Their regional reps handle feedback fast. You can count on post-sale help if you need it.

Manufacturing Capabilities

- Production capacity: Large-volume output through 26 modern factories.

- Customization: Supports OEM and private labeling, especially in Europe.

- Technology: Uses robotic cutting and welding in most production lines.

- Production type: Mostly in-house. Very little is outsourced. That keeps things consistent.

Takeaway Note

Hörmann is a great fit if you need long-lasting doors with tested performance. Perfect for hotels, resorts, or properties that need strong visual and physical security. However, they are not the cheapest, but if you’re after steady quality with fewer callbacks, they’re worth it.

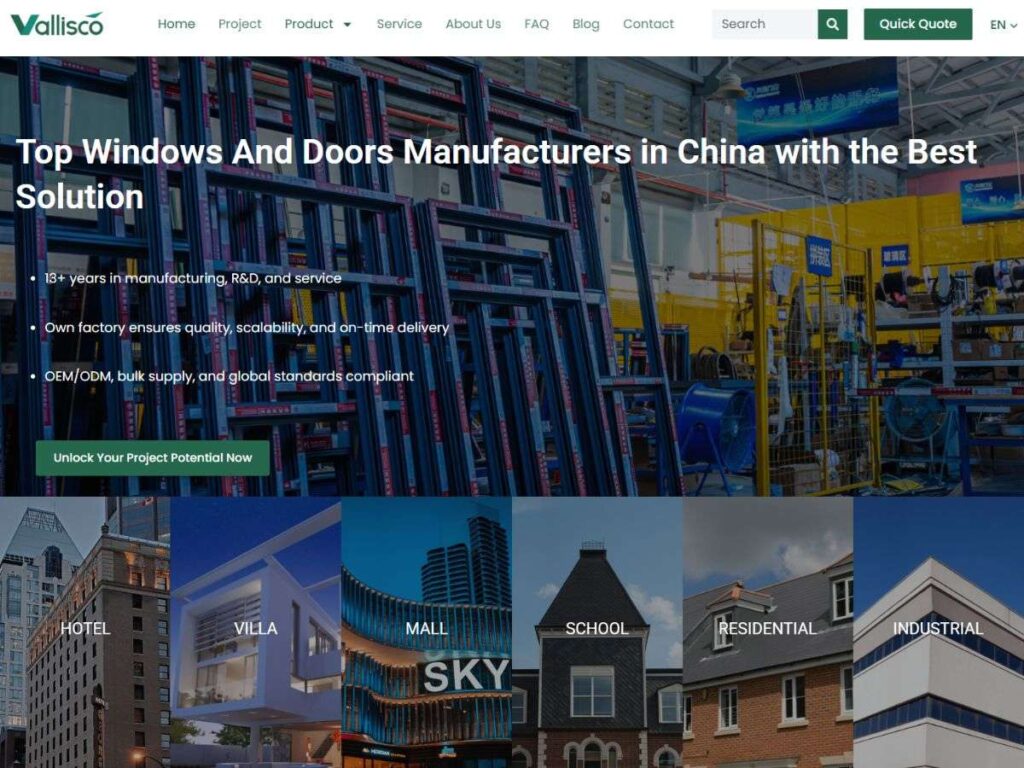

3. Vallisco

Website:www.vallisco.com

Location: No. 1926, Cao An Highway, Jiading District, Shanghai, China

Email/Phone: kelly@vallisco.com / +86 18616637186

Vallisco is a new brand launched in 2024, backed by over 13 years of experience in manufacturing doors and windows. I was introduced to them during a villa renovation project where the client wanted clean modern doors and quick responses. Vallisco stood out by providing drawings fast, adjusting specs with no fuss, and giving updates during production.

Even though the brand name is new, the team has been serving B2B clients under a parent company for years. Their focus is on project-based supply, resorts, hotels, villas, and home developments. They offer support in English and understand the export process well.

Product Range

- Front doors with glass inserts

- Entry doors with insulation

- Pivot doors with minimalist profiles

- Full door + frame sets

- Slim sliding and hinged doors

- Weather-sealed exterior door systems

Quality Control & Assurance

- Raw materials: Sourced from trusted regional suppliers. Aluminum and coatings meet export-level specs.

- Manufacturing: Factory follows documented procedures. Each order is tracked by design drawing.

- Testing: Water penetration, sealing, and surface tests done in-house.

- Third-party checks: Available upon request for certain projects.

- Customer care: Handles revisions and issues before production starts. Post-sale support available in English.

Manufacturing Capabilities

- Volume: Best suited for 20–100 door orders. Can scale for larger jobs with notice.

- Options: OEM, ODM, and private branding are available.

- Automation: Uses CNC cutting, finishing lines, and integrated quality checkpoints.

- Factory setup: Fully in-house, with packaging and loading handled by their own team.

Takeaway Note

Vallisco is a solid option for project buyers needing reliable communication and flexible solutions in Asia or Europe. While the brand is still new, their team knows the work. The only drawback is their shorter track record under the Vallisco name, which may matter if your team prefers long-established brands.

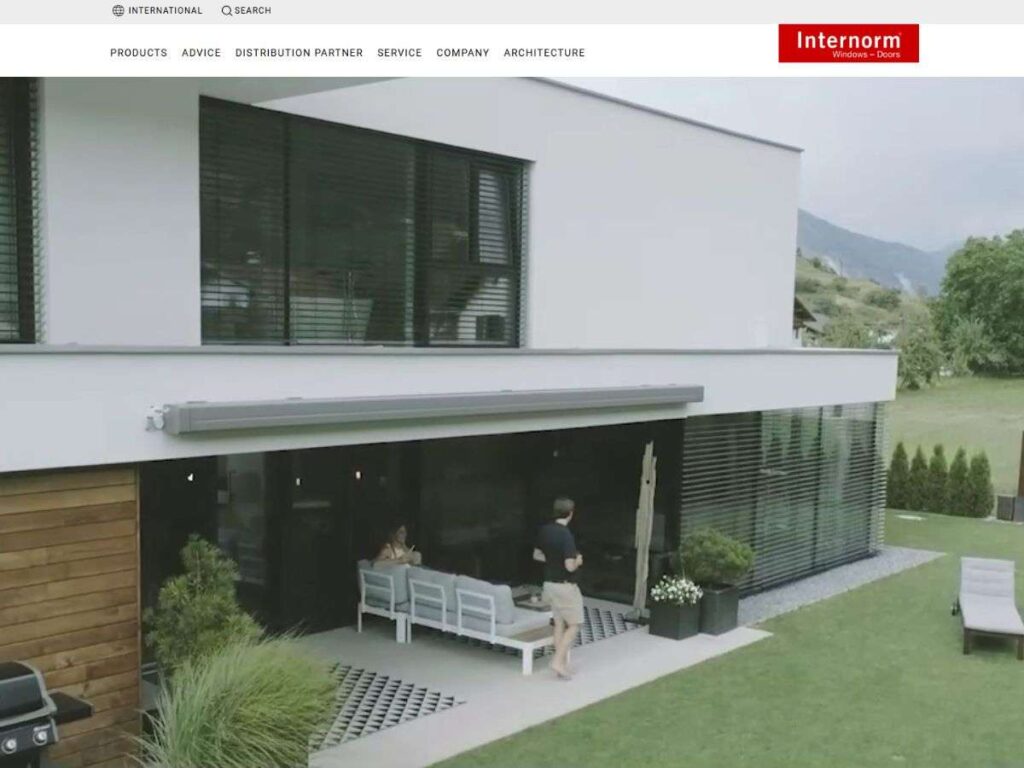

4. Internorm

Website: www.internorm.com

Location: Austria

Email/Phone: office@internorm.com / +43-7229-770

Internorm started back in 1931 and is still a family-owned company today. I’ve worked with their aluminum doors on a resort project in southern Europe. What impressed me was their precision, the fit, finish, and insulation were all excellent. They don’t just sell products. They work with you like a long-term partner.

Internorm is known for their energy-efficient doors and windows. They operate three production sites in Austria and sell across 20+ countries through more than 1,000 distribution partners. If your project is in Europe and you need excellent thermal performance or acoustic control, this brand is one to consider.

Product Range

- Timber-aluminium front doors

- All-aluminum entry doors

- Thermal glass pivot doors

- Passive-house certified doors

- Fire-rated doors

- Security doors with multiple locking points

Quality Control & Assurance

- Raw material sourcing: Uses traceable wood and aluminum from European suppliers. Each batch is recorded and matched to product lines.

- Manufacturing standards: Complies with EU standards for insulation, ventilation, and durability. Products regularly meet passive house and energy rating benchmarks.

- Testing and verification: Every door is tested for water resistance, seal strength, and thermal efficiency before packing and shipping.

- Third-party audits: External agencies audit their plants for energy, safety, and process control. Certificates are available for most product categories.

- Customer feedback: Claims are tracked and addressed through partner dealers. Support teams follow up and keep a log of issue patterns.

Manufacturing Capabilities

- Production volume: Internorm builds thousands of units monthly, with capacity to serve multi-phase hotel or housing projects in Europe.

- Customization options: Offers private label and full OEM design support, including color, finish, locking system, and thermal build.

- In-house vs outsourced: All manufacturing is done in-house at three Austrian factories. This helps them control quality and delivery schedules closely.

- Technology and automation: Plants are equipped with CNC routers, robotic handling, and energy recovery systems to improve consistency and reduce waste.

Takeaway Note

Internorm is best for projects that demand high energy performance and European certifications. Ideal for villas, passive homes, and high-end hotels. Their only drawback is price, they may not fit small budgets, especially for buyers outside Europe. But you get a long-lasting product that performs.

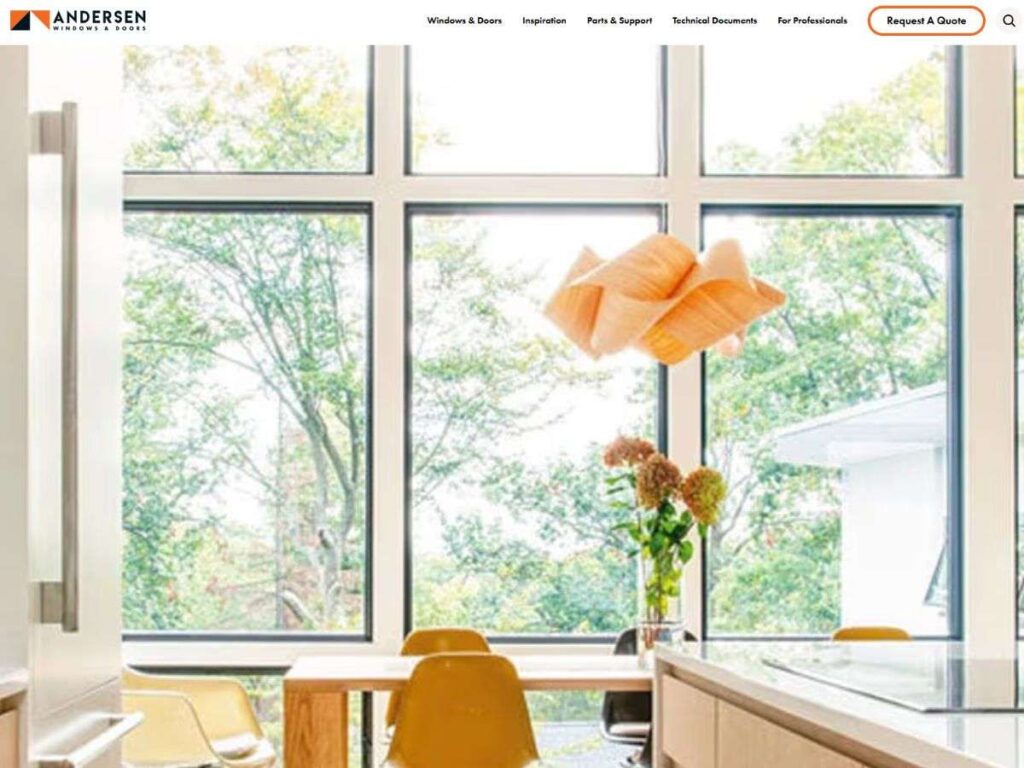

5. Andersen Corporation

Website: www.andersenwindows.com

Location: United States

Email/Phone: support@andersenwindows.com / +1-855-603-0692

Andersen has been making doors and windows since 1903. I’ve seen their products used in both residential developments and upscale hotel builds in the U.S. What I noticed most is their clean finishing and long-term durability. The doors hold up well even in high-use areas like lobby entrances and main walkways.

The company has grown into one of North America’s largest window and door manufacturers. With several plants across the U.S. and Europe, they can handle bulk orders without delay. They also support energy-efficient design and offer options with smart home integration.

Product Range

- Fiberglass entry doors

- Wood-clad exterior doors

- Steel security front doors

- Custom-size patio doors

- Storm-rated front door systems

Quality Control & Assurance

- Raw material sourcing: Uses certified wood, steel, and fiberglass. Materials are tracked by batch and checked for moisture, strength, and defect signs.

- Manufacturing standards: Meets U.S. energy codes, ADA access guidelines, and ASTM impact standards. Complies with Energy Star and LEED rating systems.

- Testing and verification: Doors go through lab testing for UV wear, impact, water, and insulation performance. Reports are available upon request.

- Third-party audits: Regular quality and safety audits done by third parties. Manufacturing locations meet ISO and sustainability certifications.

- Customer feedback: Claims are logged in a central system and resolved through service centers or dealer support. Warranty terms are clearly published.

Manufacturing Capabilities

- Production volume: High-volume production across several North American and international plants. Suitable for large property builds and repeat orders.

- Customization options: Offers private label, OEM partnerships, and full spec customizations including frame depth, glazing, hardware, and finish.

- In-house vs outsourced: Manufacturing is done in-house to maintain quality. Some specialty glass and coatings may come from certified partners.

- Technology and automation: Uses automated saw lines, robotic finishers, and custom assembly tech to improve consistency and reduce handling damage.

Takeaway Note

Andersen is a trusted partner for large-scale home and hotel projects needing stylish, high-performance doors backed by clear warranties and broad service reach. The only downside is that lead times can extend during peak U.S. demand seasons, so early planning is recommended for overseas orders.

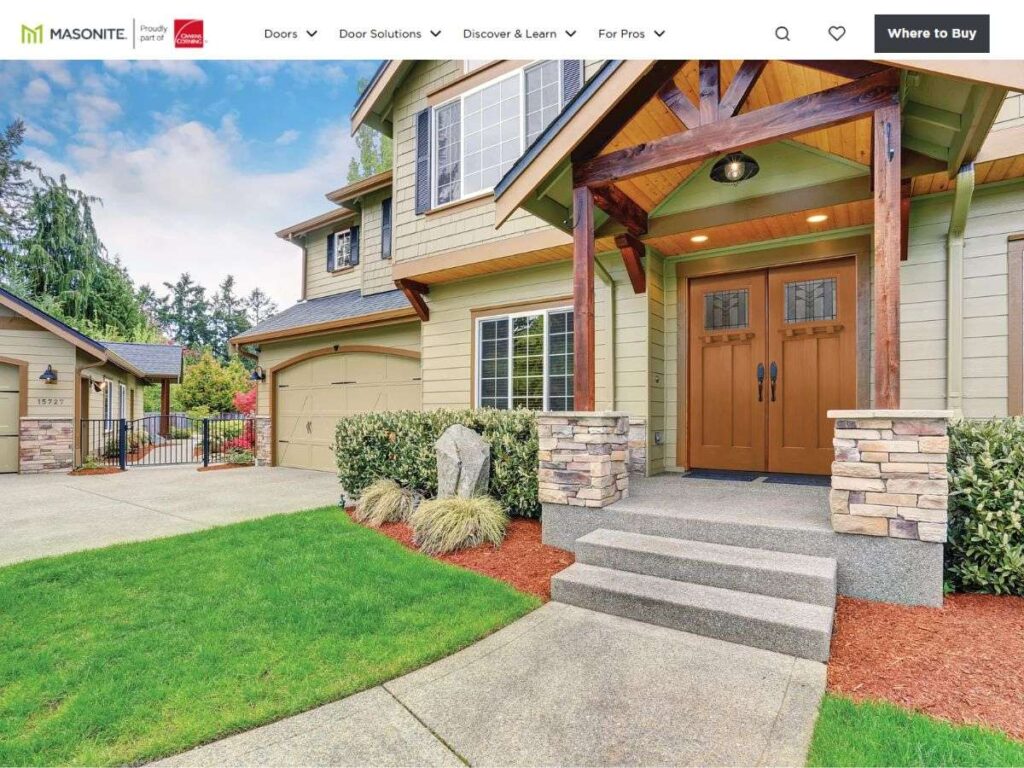

6. Masonite International

Website: www.masonite.com

Location: United States (global presence)

Email/Phone: info@masonite.com / +1-813-877-2726

Masonite started in 1925 and has grown into one of the biggest door manufacturers in the world. I’ve worked with their doors on budget hotel builds and urban apartment projects. They’re known for being practical, easy to install, consistent, and available in a wide range of sizes and finishes.

They operate over 60 facilities across North America, South America, Europe, and Asia. Their strength lies in volume and fast fulfillment. They recently joined the Owens Corning group, adding more strength to their manufacturing and logistics network.

Product Range

- Exterior steel front doors

- Fiberglass entry doors

- Solid core wood doors

- Fire-rated commercial doors

- Impact-rated exterior doors

- Panel doors with decorative glass

Quality Control & Assurance

- Raw material sourcing: Works with certified vendors for steel, fiberglass, and wood. All input materials follow internal traceability standards and are tested for defects.

- Manufacturing standards: Doors are built to meet U.S., Canadians, and select European codes for strength, insulation, and fire safety. Labels are printed with specs.

- Testing and verification: Masonite runs its own Innovation Center to test new products under real-world and lab-controlled environments for performance and wear.

- Third-party audits: Audits are done at regional plants to check safety, quality tracking, and product conformity. Reports are stored internally and by partners.

- Customer feedback: Customer claims are tracked digitally and responded to through distributors or support teams. Feedback patterns are used to improve future models.

Manufacturing Capabilities

- Production volume: Very high capacity. Ideal for housing projects, hotels, or resorts needing fast repeat orders in bulk over multiple phases.

- Customization options: Offers OEM and private label services. Clients can customize dimensions, finishes, panel layout, and hardware options based on need.

- In-house vs outsourced: Most components are made in-house. Some glass and specialty finishes are sourced from pre-approved vendors. Assembly is centralized.

- Technology and automation: Uses automated panel presses, robotic paint systems, and smart tracking tools to improve consistency and cut down on lead time.

Takeaway Note

Masonite is a strong choice for developers and engineers who need fast, consistent door supply for mid- to large-scale builds. However, their designs lean more standard than premium, better for function than standout visuals. But they’ll keep your project on track.

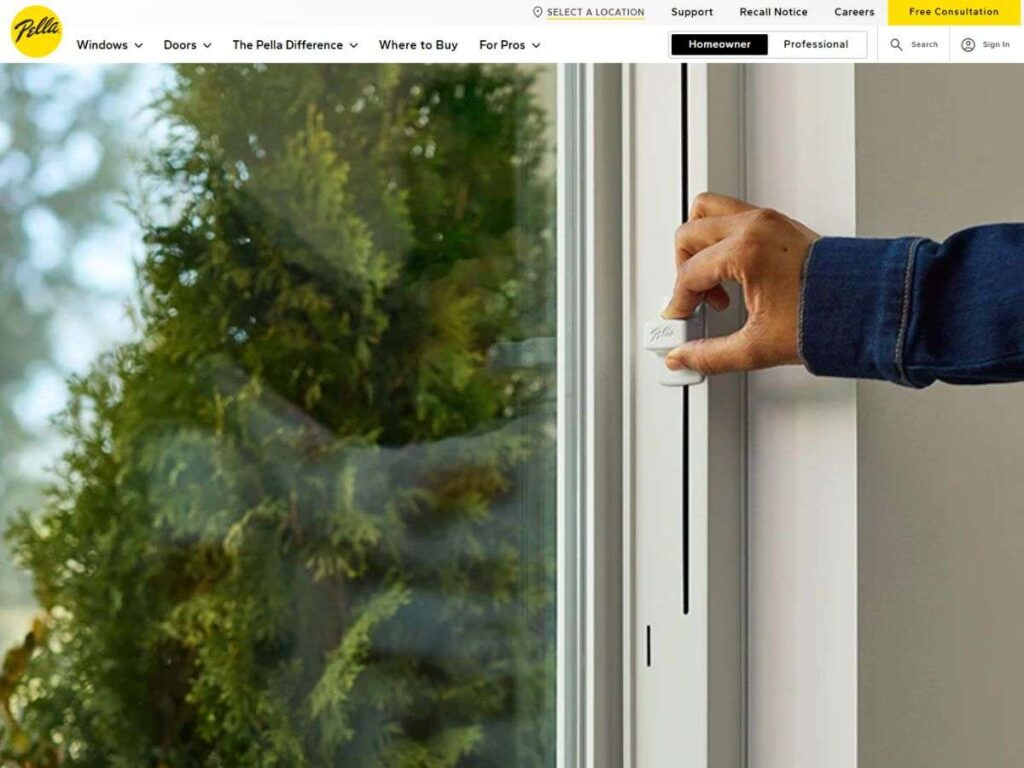

7. Pella Corporation

Website: www.pella.com

Location: United States

Email/Phone: customer.support@pella.com / +1-877-473-5527

Pella has been building doors and windows since 1925. I’ve seen their front doors used in luxury homes, boutique hotels, and design-led properties. They combine good looks with energy efficiency, which is a strong combo for projects that need long-term value.

They operate 17 manufacturing sites across the U.S. and serve projects through a dealer network and commercial division. What I like most is their balance, reliable product, stylish finish, and strong warranties. If your clients care about both performance and appearance, Pella is worth looking at.

Product Range

- Fiberglass entry doors

- Wood front doors with glass accents

- Steel security doors

- Multi-panel entry systems

- Smart lock-ready front doors

- Weather-resistant architectural doors

Quality Control & Assurance

- Raw material sourcing: Sourced from FSC-certified wood suppliers and high-grade steel mills. Each batch is tested for moisture levels, grain, and surface quality.

- Manufacturing standards: Meets U.S. residential and commercial codes, including Energy Star, NFRC, and wind zone requirements. Clear labeling helps with compliance checks.

- Testing and verification: Products are tested for insulation, seal durability, and structural integrity in lab environments simulating real climate conditions.

- Third-party audits: Facilities are reviewed by independent safety and quality auditors on a set schedule, with findings used for training and process changes.

- Customer feedback: All service tickets are logged and tracked through their CRM. Support is offered directly or through licensed local installers.

Manufacturing Capabilities

- Production volume: Can supply both single-property and multi-site orders. Multiple factories allow flexible batch sizes depending on lead time and region.

- Customization options: Offers OEM and full customizations on color, glass, trim, grille patterns, and lock hardware to match your build’s design needs.

- In-house vs outsourced: All key processes are completed in-house. Specialty glass or advanced lock systems may come from approved U.S. partners.

- Technology and automation: Uses automated sanding, precision cutting, and spray booth systems to maintain visual consistency and reduce material loss.

Takeaway Note

Pella is ideal for hospitality, villas, and homes needing stylish, energy-saving front doors with solid U.S. support. One limitation is regional focus, if you’re outside North America, delivery options and service may be more limited.

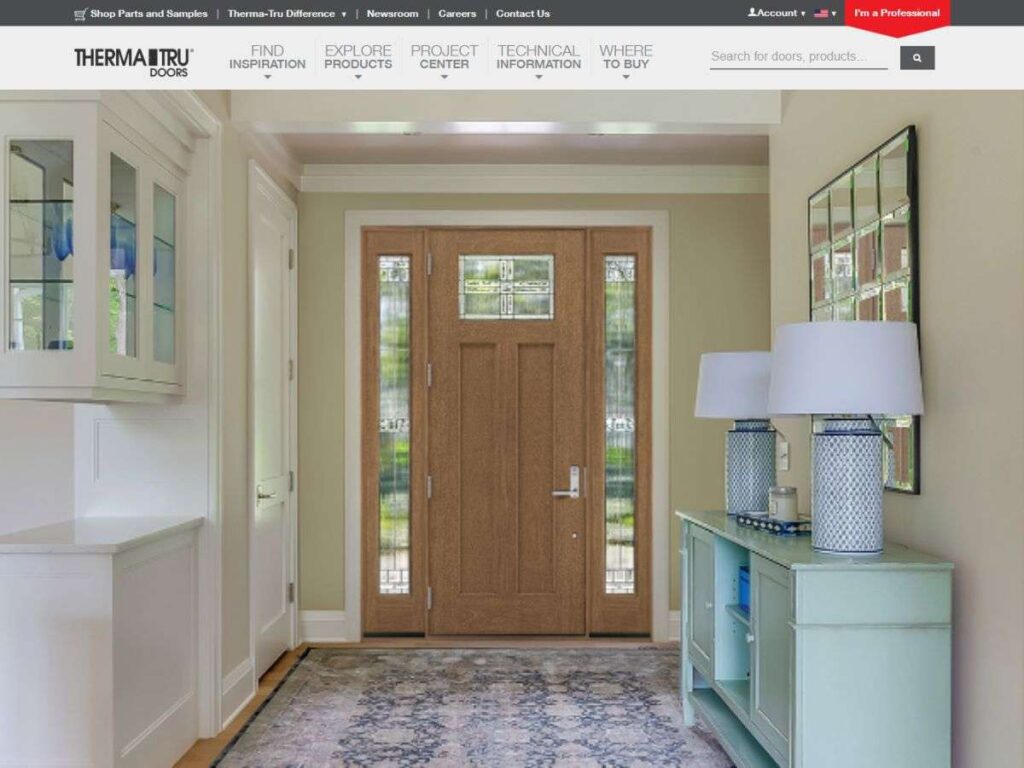

8. Therma-Tru

Website: www.thermatru.com

Location: United States

Email/Phone: customersupport@thermatru.com / +1-800-843-7628

Therma-Tru was founded in 1962 and is now one of the leading fiberglass door brands in the U.S. I’ve worked with their doors on both residential and hospitality projects, especially where moisture resistance and security were top priorities. Their fiberglass doors handle different climates well and come prehung, which saves time during installation.

They’re part of the Fortune Brands group, giving them access to resources, testing, and logistics systems that smaller manufacturers may not have. If you’re managing a build with durability in mind and want easy-to-spec options, Therma-Tru is a brand to consider.

Product Range

- Smooth-Star entry doors

- Steel security front doors

- Decorative glass panel doors

- Impact-rated storm entry systems

- Fire-rated fiberglass doors

Quality Control & Assurance

- Raw material sourcing: Fiberglass and composite materials are sourced from long-term suppliers. All components are tracked and screened before use in core or frame assembly.

- Manufacturing standards: Doors are built to meet U.S. code for impact resistance, energy performance, and safety. Fire-rated and hurricane-rated options are labeled clearly.

- Testing and verification: Products are tested for thermal transfer, surface wear, and forced-entry resistance. Each door series has passed various ANSI and ASTM standards.

- Third-party audits: Facilities undergo periodic third-party safety and quality inspections. Production lines are adjusted based on audit feedback and internal findings.

- Customer feedback: Therma-Tru logs and investigates all customer claims through service teams. Issues are resolved via warranty or replacement programs for eligible projects.

Manufacturing Capabilities

- Production volume: High-output manufacturer with capacity to handle national-scale residential and mid-size commercial projects. Common SKUs are stocked for faster ship times.

- Customization options: Offers decorative glass, sidelite, and panel layout changes. Custom sizing and finishes available for select collections. OEM support is limited.

- In-house vs outsourced: Core production and assembly are handled in-house. Some decorative glass is produced by partnered vendors to match door specs.

- Technology and automation: Uses robotic molding, precision cutting, and automated painting systems to speed up production and maintain consistent finishes on all surfaces.

Takeaway Note

Therma-Tru is a strong fit for housing and hotel projects that need moisture-resistant, low-maintenance doors with flexible style options and solid U.S.-based support. The main drawback is limited OEM flexibility. If you’re looking for full custom branding or large-scale design changes, their options may be more restricted.

Conclusion

That scratched door I mentioned earlier? We replaced it with one from a better manufacturer. Since then, I’ve learned that choosing the right supplier can save time, cost, and stress.

You’ve now seen nine manufacturers, each with strengths to match different types of projects. Whether you’re building homes, villas, or hotels, the right partner makes all the difference.

Look back at the list. Pick the one that fits your needs.

And if you want a responsive, factory-direct partner who gets project timelines, consider Vallisco. Contact us today for further details.

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

- Doors & Windows for Apartments & Hotels

- Garage Door

- Barn Door

- Sliding Window

- Thermal Break Aluminum Window

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.