I remember the first time I had to replace windows for one of our hotel projects. We needed something better, less noise, less heat, and a clean look. It was harder than expected to find the right supplier.

You may be facing the same issue now. You’re choosing windows that affect comfort, power bills, and customer satisfaction.

This review is written based on real project needs. I’ve worked with builders, engineers, and business owners like you across Southeast Asia and Europe. I’ve taken note of which manufacturers deliver, and which don’t.

You’ll find clear, honest details on 9 double pane window manufacturers. I will explain what they offer, how they work, and which type of project they fit. You won’t have to search again after reading this.

Choosing the right supplier can make or break your job.

Let’s take a look!

Quick Comparison

Choosing the right double pane window manufacturer depends on your project’s needs, volume, design, performance, or logistics. Below is a clear comparison to guide your selection:

| Manufacturer | Product Range | Manufacturing Strength | Quality Focus | Packaging & Labeling | Best For |

| Andersen | Fibrex, wood, vinyl, composite | USA-based, 30+ sites | Certified materials, strong testing | In-house, recyclable, labeled | Large builds needing stable delivery |

| Pella | Wood, vinyl, fiberglass | 20 factories, broad distribution | Feedback-driven, third-party verified | Custom-labeled, eco-conscious | Energy-focused projects needing variety |

| Vallisco | Aluminium, glass wall, sliding systems | Own factory, export-ready | Factory-controlled, new brand checks | Export-safe, project branding | Villa or hotel projects in SE Asia, Europe |

| Internorm | Timber/aluminium, uPVC | Fully in-house, Austria-based | Deep testing, smart tech integration | CE-labeled, recyclable | EU-standard projects with smart options |

| Oknoplast | PVC, aluminium, shutters | High automation, 6 sites | ISO, thermal-first design | Recyclable, smart labeled | Volume orders with design flexibility |

| NorDan | Wood, timber/aluminium | Nordic group, multi-site | Forestry traceable, ISO audited | CE-labeled, project-coded | Sustainable hotels, homes, cold-weather zones |

| Technal | Aluminium, curtain walls | EU-based, certified fabricators | R&D driven, strong installer system | Foam-free, crate-ready | Architect-driven or curtain wall needs |

| G.James | Glass + aluminium window/door systems | Australian-owned, local control | National standards, lab-tested | Recyclable, export-ready | Builds in SE Asia needing AU-grade supply |

| Reynaers | High-end aluminium systems | EU production, 70+ countries | CE/EN certified, smart R&D focus | Premium packaging, tracked labels | High-spec commercial or villa façades |

Use this table as a quick guide. To read full details on each manufacturer, scroll down to their individual reviews above.

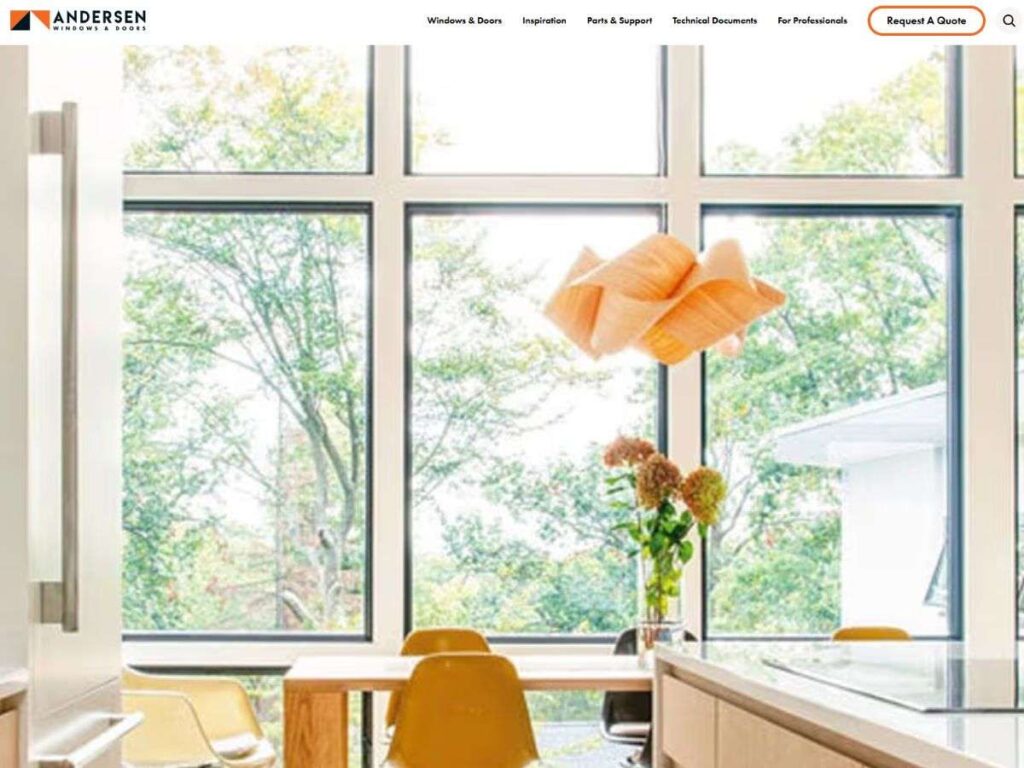

1. Andersen Corporation

Andersen is one of the most well-known window manufacturers in the United States. They’ve been building windows since 1903. That’s over 120 years of experience.

I’ve worked with teams who used Andersen products in hotel, villa, and residential jobs. The feedback is often solid, good insulation, durable frames, and support that actually responds.

Andersen is based in Minnesota, but they serve international clients too. With over 30 manufacturing and distribution sites, they’re big enough to handle large projects across markets.

They offer different frame materials, energy-saving glass, and certified performance. If your project needs reliable lead times and consistent build quality, Andersen is one of the safer choices.

Product Line

- 400 Series

- A-Series

- E-Series

- 100 Series

- Renewal by Andersen

Quality Control & Assurance

- Material Sourcing: Uses certified wood and composite sources. Supply chain is tracked for each unit batch, helping reduce unknown defects.

- Manufacturing Standards: Factories follow U.S. energy and safety standards. Most products are Energy Star® rated, with internal process checks at each stage.

- Testing Process: Windows are tested for water, wind, and impact resistance. Results guide product updates and customer support advice.

- Third-Party Audits: Regular audits from outside firms help keep the quality consistent across all factory locations and product lines.

- Customer Feedback Handling: Dedicated team handles complaints. Warranty claims are tracked. They follow up when issues are raised and keep data for review.

Future Plans & Growth Strategy

Andersen is investing more in composite frame materials. Fibrex® is one of their core focus areas. It mixes recycled wood and polymers for strength and insulation.

They’re also expanding their capacity. In 2023, they added a new facility in Arizona. This is helping shorten delivery times in the western U.S., and may help exports.

In terms of product direction, they’re keeping up with energy codes and shifting more models toward passive-house levels of performance.

Packaging & Labeling

- In-House Packaging: Andersen packs products directly at their own factories using custom-fit corners and secure wrap. This helps protect windows during long shipping and job site handling.

- Custom Branding: For larger orders, Andersen can add project-specific tags or job references. This makes it easier to manage multiple units across active building sites.

- Labeling Compliance: All units come labeled with performance ratings and compliance tags, including NFRC and Energy Star. These meet common codes in the U.S. and export markets.

- Sustainability: They’ve improved their packaging to reduce waste. Most materials are recyclable, and they’ve moved away from heavy plastic and foam-based packing materials.

Bottom Line

Andersen is a solid choice if you need high-volume, dependable windows for villas, hotels, or homes. Their quality control reduces delays and keeps site work moving.

However, because their products cost more than many vinyl-only brands, they may not suit very tight budgets or fast-turnaround builds where price is the top concern.

Reach Them

- Website:https://www.andersencorporation.com

- Location: Bayport, Minnesota, USA

- Contact: +1-651-264-5150 / info@andersencorp.com

2. Pella Corporation

Pella is an established U.S. window and door maker. They began in 1925 in Pella, Iowa and still operate there. They now employ around 7,000 people and run about 20 factories in the U.S. and Canada (Wikipedia).

I’ve seen Pella work well on commercial and hotel projects. Their windows are durable, low maintenance, and energy efficient. They earn praise for clear technical specs and support for professional clients.

They offer wood, vinyl, and fiberglass options. They also integrate blinds, impact-resistant glass, and smart systems. Their products match energy codes across many markets.

Product Line

- Reserve™ Traditional Wood

- Lifestyle Series

- Impervia® Fiberglass

- 250 Series Vinyl

- Encompass by Pella®

Quality Control & Assurance

- Material Sourcing: Pella sources sustainable wood and certified components. They track materials and manage forest stewardship across suppliers.

- Manufacturing Standards: They follow U.S. building codes. Products meet NFRC and Energy Star ratings. They audit factories regularly.

- Testing & Verification: Windows are tested for impact, sound, wind, and water. Internal results inform design updates and installer training.

- Third‑Party Audits: Independent reviews verify design, process, and performance. They maintain certifications with WDMA and USGBC.

- Customer Feedback Handling: Dedicated teams manage complaints and warranty claims. Reports track resolution and drive product improvements.

Future Plans & Growth Strategy

Pella continues to focus on new high-performance lines. They enhance low‑e glass and insulated glazing options for hot or cold climates.

They also invest in remote control and hidden screen systems. Their R&D covers smart shading and climate-responsive glazing.

Over the next few years, they will expand digital tools for professional partners. They provide BIM files and specs via planning documents to help engineers and project planners (Pella).

Packaging & Labeling

- In-House Packaging: Pella packs products at their facilities. Packages include protective cushioning to guard against shipping or site damage.

- Custom Branding: For bulk or repeat projects, labels can include project name, order details or company identity.

- Labeling Compliance: Each unit features NFRC and Energy Star labels. This ensures compliance with building and export regulations.

- Sustainability: Packaging uses recyclable cardboard and minimal plastic. They reduce waste and emphasize eco‑friendly materials.

Bottom Line

Pella is best if you value energy efficiency and detailed product planning. Their windows support professional engineering and spec-driven projects. However, some product lines cost more than basic vinyl options, so if your budget is slim or low-cost is key, you may find cheaper alternatives.

Reach Them

- Website:https://www.pella.com/

- Location: Pella, Iowa, USA

- Contact: +1-877-473-5527

3. Vallisco

Vallisco is a newer brand based in China. The company started its independent brand operations in 2024 but has over 24 years of background in manufacturing through its parent group. They specialize in aluminium windows and doors with double pane options for hotels, villas, and homes.

I’ve seen Vallisco grow fast in Southeast Asia and Europe. What stands out is their clear communication, fast delivery times, and strong focus on export projects. Their systems are designed with project builders in mind, not one-time buyers.

They own their factory, manage quality control directly, and keep a close eye on every part of the build and delivery process.

Product Line

- Double Pane Sliding Windows

- Casement Windows with Thermal Break

- Lift & Slide Door Systems

- Fixed Picture Windows

- Glass Wall Systems

Quality Control & Assurance

- Material Sourcing: Vallisco uses certified aluminium and glass. All materials are traceable from supplier to finished product, reducing unknown quality risks.

- Manufacturing Standards: Factory follows ISO-certified procedures. They build to export-quality standards and test every order before packaging.

- Testing & Verification: Each unit goes through checks for water leaks, frame finish, seal strength, and opening function before shipping.

- Third‑Party Audits: Partner audits and customer-side inspections are welcomed. Certificates are shared openly upon request.

- Customer Feedback Handling: Orders are tracked closely. Service team responds fast to feedback, and adjustments are made based on buyer input.

Future Plans & Growth Strategy

Vallisco is focused on growing in Southeast Asia and Europe. They’re targeting villa and resort projects where full window and door replacement is needed.

They are adding new machinery to expand capacity and speed. Their team also plans to roll out new glass options with better thermal control in the coming year.

Partnerships with hotel builders and design firms are in progress. These will help them enter more commercial-grade jobs outside China.

Packaging & Labeling

- In-House Packaging: Products are packed inside their own factory using corner protectors, film wrap, and shrink layers for safety.

- Custom Branding: Labels can include your logo, project ID, or part numbers to match your on-site needs.

- Labeling Compliance: Export documents, technical specs, and barcode labels follow import rules in target markets like the EU or ASEAN.

- Sustainability: They use recyclable cardboard and avoid foam fillers. Packing volume is planned to fit standard shipping sizes.

Bottom Line

Vallisco is a strong fit for full-property window upgrades, especially in villas and hotels needing export-ready products and responsive service.

That said, as a newer brand, they are still building trust and visibility. Some buyers may prefer more established names until Vallisco proves itself further in global markets.

Reach Them

- Website:https://vallisco.com/

- Location: No. 1926, Cao An Highway, Jiading District, Shanghai, China

- Contact: +86 18616637186 / kelly@vallisco.com

4. Internorm International GmbH

Internorm began in 1931 in Traun, Upper Austria. It was a small metal workshop. Over the decades, it grew into Europe’s leading window and door brand.

I’ve seen Internorm used in high-end hotel and villa builds across Europe. Their products stand out for precision engineering and solid performance. They build every component in Austrian factories.

They run three production sites: Traun, Sarleinsbach, and Lannach. They make PVC, PVC‑aluminium, and wood‑aluminium windows. They handle extrusion and tempered glass production in‑house.

All parts, from frame to glass, are under their control. If you need consistent quality for large builds, they offer a dependable system.

Product Line

- PVC Windows

- PVC/Aluminium Windows

- Timber/Aluminium Windows

- Lift & Slide Doors

- Frameless Panorama Windows

Quality Control & Assurance

- Material Sourcing: All frames, glass, and hardware are made in‑house in Austria. This limits external supply risks and ensures traceability.

- Manufacturing Standards: Units are made in 3 Austrian sites under ISO-level standards. They follow internal and external process checks.

- Testing & Verification: Products are tested for thermal insulation, weather tightness, and structural strength. New models are adjusted from test results.

- Third‑Party Audits: Independent audits verify I‑tec technologies and system safety. Certifications remain valid across export markets.

- Customer Feedback Handling: Certified installation partners install units. They inspect post-install and log feedback. Support teams act on site comments.

Future Plans & Growth Strategy

Internorm continues investing in its I‑tec system. This includes smart ventilation, shading, and locking technology. They aim to keep leading with system-level innovation.

They plan gradual capacity growth in existing Austrian plants. No new factories announced, but they maintain strong output from Traun, Sarleinsbach, and Lannach.

They also expand share in European markets via more sales partners and technical support. Their goal is higher export volume from Austrian production.

Packaging & Labeling

- In-House Packaging: All units are packed at Austrian factories using durable corner protectors and film wrap to prevent damage in transit.

- Custom Branding: For big projects, you can ask to include project codes or architecture firm names on labels and crates.

- Labeling Compliance: Each unit includes an NFRC-style label with thermal U-values, glazing ratings, and CE marking for EU export.

- Sustainability: They use recyclable cardboard and minimal plastic. Packaging is designed to reduce waste in shipping and onsite unpacking.

Bottom Line

Internorm works best for professional projects in Europe or SE Asia where build quality must be consistent across many units. Their full control means fewer surprises on site.

That said, because they operate from Austria with in-house production, lead times and cost may be higher for far-flung markets that rely on export.

Reach Them

- Website: https://www.internorm.com/

- Location: Traun, Upper Austria, Austria

- Contact:contact form

5. Oknoplast Sp. z o.o. (Poland)

Oknoplast started in 1994 near Kraków, Poland. They originally made PVC windows. Later, they added aluminium and roller shutters. Today, they run six factories in Poland and Spain. They can produce over 2.3 million units per year. Around 3,500 outlets in Europe and North America carry their products (Wikipedia).

I’ve seen Oknoplast used in large hotel and villa projects. They focus on clean design, thermal performance, and consistent delivery. You feel confident when you work through professional partners. They customize per market needs and climate zones.

Product Line

- PVC Double Pane Windows

- Aluminium Double Pane Windows

- Tilt & Turn Window Systems

- Patio Doors

- Accessories (shutters, blinds)

Quality Control & Assurance

- Material Sourcing: Aluminium and PVC profiles come from VEKA and trusted partners. They maintain traceability and high consistency.

- Manufacturing Standards: Factories in Poland and Spain use ISO and industry norms. Automation reduces human error.

- Testing & Verification: Units are tested for U-value, wind, water, and comfort. Innovative glazing like Ug = 1.0 is standard.)

- Third‑Party Audits: Certifications include CE, NFRC, IFT. External audits ensure design and performance meet export rules.

- Customer Feedback Handling: Support teams review installer and client feedback. Changes are tracked. Repeat orders show trust from partners.

Future Plans & Growth Strategy

Oknoplast is investing heavily in automation. In late 2023, they added a fully automated high-bay warehouse to speed deliveries and manage stock more efficiently.

They plan further growth in Europe and North America. They support partners via technical tools, showroom networks, and logistics for large volume builds.

Their R&D keeps updating thermal glazing, new frame finishes, and integrating energy-efficient options into new models.

Packaging & Labeling

- In‑House Packaging: Windows are secured in factory packaging with protectors and shrink wrap. This prevents damage during transport and handling.

- Custom Branding: Bulk orders can include project tags, barcodes, and your logo. This helps track units across big sites.

- Labeling Compliance: Each unit includes CE marking, NFRC or IFT labels, and thermal data. Labels meet EU and export regulations.

- Sustainability: Packaging uses recyclable materials. Foam is minimized. Cardboard is designed for reuse or recycling.

Bottom Line

Oknoplast suits professional projects like villas, hotels, or hotels in Europe and SE Asia needing high volume and good thermal insulation. They deliver consistently and support logistics well.

That said, as they continue building global visibility, some engineering teams may choose more familiar legacy brands first while trust in Oknoplast spreads.

Reach Them

- Website:https://oknoplast.com/ or https://oknoplast.com.pl/

- Location: Ochmanów / Kraków, Poland

- Contact: +48 12 279 71 71

6. NorDan Group

NorDan began in 1926 in Moi, Norway. It is still family owned and guided by early values. Over the decades, it expanded across Scandinavia and Poland. Today NorDan has twelve factories in Norway, Sweden, Poland, Lithuania, and Denmark, serving professional clients across Europe and other regions.

I have worked alongside engineering teams on large hotel and villa jobs. NorDan’s timber and aluminium windows perform reliably in cold, humid or warm climates. They support smart accessories like energy‑efficient glazing and solar-integrated systems.

Over time, NorDan earned trust in project markets. They deliver tools and data you can plan with. You get consistency and support through established distribution networks.

Product Line

- Wooden double pane windows (tilt & turn, casement)

- Timber‑aluminium composite windows

- Lift & slide door systems

- Smart accessory systems (e.g. SolarGuard)

- SoundGuard & StormGuard variants

Quality Control & Assurance

- Material Sourcing: Uses sustainably sourced wood certified by European forestry schemes. Traceability maintained from sawmill to factory.

- Manufacturing Standards: Follows ISO 9001 procedures and internal quality checks across all six group factories. Consistency is measured.

- Testing & Verification: Windows tested for thermal insulation, wind, sound, and water. Failures lead to design refinement.

- Third‑Party Audits: Certifications confirmed by independent bodies. NorDan shares certificates and welcomes on-site inspections.

- Customer Feedback Handling: Regional offices collect partner feedback. Support staff track issues and resolve them per project.

Future Plans & Growth Strategy

NorDan plans to invest in sustainable solutions. They took a stake in glass‑tech startup Hybridized to reduce carbon footprint in window designs.

They also partner with Saint‑Gobain to align with EU building performance directives. Their R&D focuses on solar-integrated glazing and smart accessory systems.

Across the next few years, they aim to grow export volume from their existing Nordic and Polish factories. They support project partners with stronger technical service and distribution reach.

Packaging & Labeling

- In‑House Packaging: Units are packed at NorDan factories with sturdy corner guards, foam padding, and wrap to protect during multi-leg shipping.

- Custom Branding: Packaging can include project codes, serial numbers, or client logos for professional job tracking on site.

- Labeling Compliance: Each unit ships with CE labeling, thermal U‑value data, material type, and import/export documentation.

- Sustainability: They use recyclable cardboard and minimal plastic based on Nordic environmental standards to reduce waste.

Bottom Line

NorDan suits full-scale builds, villages, hotels, villas, where quality and sustainability matter. You get precision-engineered windows and solid support across Europe and Southeast Asia.

However, as a heritage Nordic brand, their setup may be less familiar to teams outside Europe. Therefore, lead times and logistics may feel more complex in new markets.

Reach Them

- Website:https://nordangruppen.no/en/

- Location: Moi, Norway (HQ); factories in Norway, Sweden, Poland, Lithuania

- Contact:PR contacts

7. Technal

Technal was founded in 1960 in Toulouse, France. It began as Alusud and later became Technal under Hydro group. Today it serves architects, installers, and building owners worldwide.

I’ve seen Technal used in European hotel and villa builds. Their aluminium systems are precise, modern, and built for durability. Their certified network ensures correct fabrication and installation.

They produce and test systems in Toulouse based R&D labs. Performance data and test results are shared easily. They support both design planning and large project deliveries.

Product Line

- Casement Aluminium Windows

- Sliding Aluminium Windows

- Bi-fold Doors

- Curtain Wall Systems

- Aluminium Balustrades

Quality Control & Assurance

- Material Sourcing: Uses Hydro aluminium profiles from certified sources. Materials tested for strength and traceable to extrusion origin.

- Manufacturing Standards: Factories follow ISO standards. Certified installer network (“Technal Aluminier”) ensures quality fabrication and fitting.

- Testing & Verification: Products undergo lab testing for thermal, water, wind, and structural performance. Results guide product approvals.

- Third‑Party Audits: External bodies validate product compliance with EU and international norms. Certificates are kept current.

- Customer Feedback Handling: Regional teams collect feedback from installers and project clients. Improvements tracked and applied.

Future Plans & Growth Strategy

Technal plans to deepen R&D in aluminium glazing and structural solutions. Their Toulouse centre develops new profiles and test methods.

They also push global growth via certified installer networks. Expansion includes more partners in Southeast Asia and new EU countries.

They aim to integrate recycled aluminium into profiles and improve thermal performance for upcoming building codes.

Packaging & Labeling

- In-House Packaging: Technal packs systems using protective foam strips, wooden crates, and stable pallets to avoid damage in transit.

- Custom Branding: Large projects can feature company or project logos on crates and labels for tracking on site.

- Labeling Compliance: Each system is labeled with CE marking, thermal data, and batch codes. Labels meet EU export standards.

- Sustainability: Packing materials are recyclable. They use minimal plastic and favour reusable crates to reduce waste.

Bottom Line

Technal is great for architectural, villa, or hotel use when you need aluminium systems that plan well and deliver high performance.

That said, as a European-based system supplier, it may feel less accessible if you’re in less-established markets. Import and support may be slower outside their installer network.

Reach Them

- Website: https://www.technal.com/fr-fr/professionnels

- Location: Toulouse, France

- Contact: via contact form

8. G.James Glass & Aluminium

G.James began in 1917 in Brisbane, Australia. It started by cutting glass for joiners. Over time, it evolved into a full glass and aluminum fabricator. Today, it has about 2,500 employees.

I’ve seen G.James used in large hotel and villa builds in Australia and nearby regions. Their glass processing and aluminium window systems are trusted for precision and durability. They handle double-pane production themselves in Australia.

They support professional engineers and builders with technical specs, custom fabrication, and project logistics. They can scale for volume and still maintain high quality on every delivery.

Product Line

- Double Pane Aluminium Window Systems

- Aluminium Sliding Doors

- Aluminium Casement and Awning Windows

- Custom Glass Facades and Curtain Walls

- Retractable Screen and Bifold Systems

Quality Control & Assurance

- Material Sourcing: Aluminium and glass sourced and processed in-house. Traceability ensures consistency from stock to final build.

- Manufacturing Standards: Factories follow Australian standards AS2047, AS2208 and ISO practices. Automated lines reduce error.

- Testing & Verification: Each unit is tested for thermal value, water tightness, and wind load. Products meet performance standards.

- Third‑Party Audits: External bodies audit glass and frame quality. Certifications are kept current and available on request.

- Customer Feedback Handling: Regional teams collect input from builders. They resolve issues quickly and track trends to improve process.

Future Plans & Growth Strategy

G.James is scaling its glaze processing and export capacity. They’ve invested in new glass furnaces and aluminium extrusion capability.

They plan to support more large villa and hotel clients in Southeast Asia. Their focus is on custom glazing, automation, and tighter delivery schedules.

Their R&D next steps include low‑energy glass coatings, smart shading options, and façade systems to meet rising global performance codes.

Packaging & Labeling

- In-House Packaging: Each window system is packed at local Australian plants. Custom pallets and padding ensure safe transit over long distances.

- Custom Branding: For commercial orders, labels can include project codes, part numbers, or installer ID for easy site handling.

- Labeling Compliance: Comes with AS-certified labels, thermal ratings, material data, batch codes, and export paperwork.

- Sustainability: Packaging is mostly recyclable cardboard. Foam is minimal. They follow Australian recycling rules and waste reduction goals.

Bottom Line

G.James is ideal for Australia‑based or Southeast Asia projects needing high‑quality double pane aluminium systems, local support, and fast service.

However, as a regionally focused firm, they may lack global recognition outside Australasia. International partners may need to confirm logistics and support before choosing them.

Reach Them

- Website: https://gjames.com/

- Location: Brisbane, Queensland, Australia

- Contact:inquiry form

9. Reynaers Aluminium

Reynaers Aluminium was founded in 1965 near Antwerp, Belgium. They started as a small foundry and now serve global architecture and construction markets. With over 3,000 staff and customers in more than 70 countries, they offer tailored aluminium systems for high-end projects.

I’ve seen Reynaers used in upscale villas, boutique hotels, and commercial builds across Europe and Asia. Their strength is detailed engineering, award‑winning façades, and panels made for comfort and energy savings.

Their R&D and fabrication centers operate across Belgium, Germany, and the Netherlands. They support architects and engineering teams with detailed BIM files and performance data you can build from.

Product Line

- CP 155‑LS Lift & Slide Systems

- CS 86‑HI Casement Window Systems

- SlimLine 38 Sliding Systems

- MasterLine 8 Curtain Walls

- SlimLine 68 Windows & Doors

Quality Control & Assurance

- Material Sourcing: Uses high-grade Hydro aluminium. Traceable to alloy batch. Ensures strength and consistent finish across all units.

- Manufacturing Standards: Factories follow ISO 9001 and European QM codes. All sites maintain identical process rules for consistent performance.

- Testing & Verification: Products are tested for wind, water, sound, and thermal insulation in certified labs. Failures prompt immediate design updates.

- Third‑Party Audits: Accredited external testing bodies sign off on compliance with CE, EN standards, and export norms.

- Customer Feedback Handling: Global tech support collects B2B feedback. Regional teams track issues and suggest product refinements for future builds.

Future Plans & Growth Strategy

Reynaers continues R&D in high-performance glazing and structural façades. They invest in passive-house performance upgrades and integrated shading systems.

They plan to open a new fabrication and logistics center in Eastern Europe by mid-2026. This will help speed delivery in EU and Asia markets. They also partner with architects and façade specialists to co-develop future mixed-glass systems.

Packaging & Labeling

- In‑House Packaging: Reynaers packs systems in their plants using custom crates, corner protection, and shrink wrap that meet shipping standards and resist transit damage.

- Custom Branding: For large projects, panels and frames are labeled with project codes, part numbers, and client or architect details for easy onsite sorting.

- Labeling Compliance: Each shipment includes CE marking, thermal performance labels, alloy type, and barcodes per export regulations.

- Sustainability: Packaging uses recycled cardboard and re-usable wooden crates. They reduce foam use and use green-certified materials.

Bottom Line

Reynaers fits projects that demand refined design, high insulation, and architectural precision in villas, hotels, and commercial builds. They offer strong support for engineering and design planning.

However, since they are premium and global, they tend to be more expensive, and delivery timelines may be tighter for projects outside core EU and Asia hubs.

Reach Them

- Website:https://www.reynaers.com/

- Location: Duffel, Belgium (HQ); production across Europe

- Contact: via online professional contact form or local partner network

Conclusion

Back when I helped that hotel find the right windows, we had no guide, just calls, delays, and trial runs. You don’t have to go through that.

This review gave you a solid look at nine trusted manufacturers. You’ve seen their strengths, specialties, and what they’re best at.

Now it’s your turn to choose what fits your project.

If you’re working on a villa, hotel, or house in Southeast Asia or Europe, Vallisco is ready to support you with strong products and reliable export service.

Contact us today to get started with your project planning.

Explore Related Resources

Want to see more? We’ve gathered additional product choices to give you even more variety:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.