I used to struggle with door suppliers. Some looked good on paper, but the quality didn’t hold up after a few months. Others had strong products, but support was slow, and communication didn’t work.

If this sounds familiar, you’re not alone. I’ve been there too.

That’s why I put this list together. We’ve worked closely with many double rebated composite door manufacturers. I know what to look for, and I know what makes a supplier reliable.

In this article, you’ll find clear, honest reviews. You’ll see what each manufacturer does well and where they may fall short. Whether you’re replacing doors for a hotel or fitting out villas, this guide will help you move forward.

Finding the right partner saves time, money, and future headaches.

So let’s get started!

Quick Comparison Chart

Many of these manufacturers offer strong double rebated door options, but each one fits different project needs. Use this table to compare them at a glance.

| Manufacturer | Product Focus | Design Range | Lead Time | Export Support | Best For |

| Internorm | Timber-aluminium composite doors | Modern + traditional | 4–6 weeks | Strong (EU + Global) | Villas, hotels in cold climates |

| Hörmann | Steel/aluminium double rebated entry systems | Modern, secure | 5–7 weeks | Yes | Hotels, commercial sites, large builds |

| Vallisco | Factory-direct composite and aluminium doors | Custom, wide color options | 25–35 days | Yes (Asia, EU) | Villas, hotels, multi-door housing projects |

| The Palladio Collection | Fiberglass composite doors with heritage designs | Classic, decorative | 3–5 weeks | Limited | Guesthouses, villas with traditional style |

| Comp Door | Timber-core composite doors | Classic and contemporary | 2–3 weeks | Limited (UK-based) | House upgrades, small hotel refits |

| Distinction Doors | Foam-core slabs for fabricators | Wide color + glazing | 10–20 days | Limited (bulk only) | Fabricators, housing developers |

| Hurst Doors | Double rebated trade doors | Decorative + functional | 5–7 days | Limited | Installers, fast-moving projects in UK |

To read more about each manufacturer, their strengths, and door styles, check out the full reviews below.

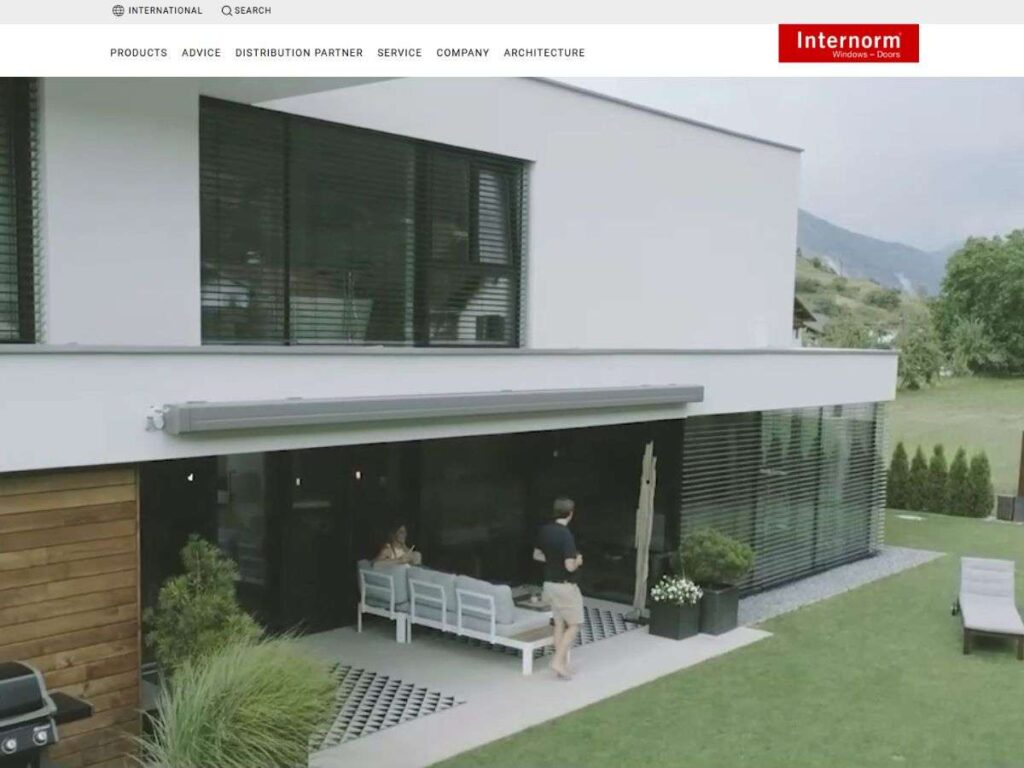

1. Internorm

I first came across Internorm while working with a hotel group in Central Europe. We needed doors that could perform in colder climates with tight energy rules. Internorm stood out not just for looks, but for long-term reliability.

They’ve been around since 1931. That’s nearly 100 years of window and door making. They’re still family-owned, which you’ll feel in their care and product consistency. Their quality control is strong, and they build all their doors in Austria. That helps keep the standards high.

Product Range

- KF 520 Composite Door: Slim frame with integrated locking. Good for modern houses or villas. The sash hides behind the frame for a clean look.

- HT 410 Timber-Aluminum Door: Offers a wood finish inside, metal outside. Looks great in warm settings like inns and older homes needing thermal performance.

- AT 540 Entrance Door: Secure and highly insulated. Great for hotels or buildings with high foot traffic. Includes double rebated seals by default.

- KF 510 Security Door: For higher protection. Includes I-tec Locking system and extra insulation. Useful in urban hotels or private homes with street access.

- Sliding Door KS 430: Not a main door, but often paired with rebated entry doors in villas or garden homes. Solid frame and weather seals.

Lead Times & Production Turnaround

- Average Production Time: Most orders are completed in 4 to 6 weeks, depending on design and season. Standard designs are often faster than custom ones.

- Order Workflow: Orders go through local dealers who confirm specs, submit designs, and pass them to Internorm’s Austria factory for build and QC.

- Rush Orders: Dealers can request faster production for standard doors, often trimming 1–2 weeks off normal lead time during low-traffic periods.

- Delays Possible: Expect longer lead times during peak seasons, custom glazing orders, or if shipping constraints affect material arrival or outgoing freight.

Supply Chain & Logistics

Internorm builds all doors in Austria, keeping quality consistent from start to finish. Their team works with European suppliers for hardware, insulation, and coatings.

Shipping is handled through a wide network of local dealers. They support both domestic and international delivery. Freight coordination and customs paperwork are managed directly with you or your installer.

The doors are packed with care, minimizing the chance of damage during transit. I’ve personally seen their packaging stand up well on long trips.

Final Verdict

Internorm is a strong choice for villas, hotels, and projects needing thermal and acoustic performance. That said, you’ll need to work through official dealers, and pricing is higher than many regional brands.

2. Hörmann

The first time I worked with Hörmann was for a commercial villa compound in southern Europe. We needed reliable doors that would hold up over time. Hörmann’s team helped us work through design choices and delivery steps without fuss.

They’ve been in the door industry since 1935. That kind of history shows in how they organize production, design, and support. With over 6,000 employees and operations in over 40 countries, they’re built to handle scale.

Product Range

- Thermo65 Entrance Door: Features a 65mm steel door leaf, double sealing, and thermal break. Great for buildings in colder regions needing high insulation.

- ThermoSafe Door: A 73mm aluminum frame with triple thermal seals. Strong U-values and built-in security features. Good fit for urban villas or guesthouses.

- TopComfort Door: All-glass look with security glazing and hidden seals. Best for modern homes and resort entries that want design without losing performance.

- KSi Security Doors: Steel core doors for secure rooms, storage areas, or high-risk entries. Often used in hotels and offices for added safety.

- RollMatic Garage Doors: Optional add-on. Good for garages paired with main entrance doors. Consistent look and shared control system.

Lead Times & Production Turnaround

- Average Production Time: Most composite door orders are completed in 5 to 7 weeks. Custom security upgrades and glazing can add time.

- Order Workflow: Orders go through certified local dealers. They handle spec review, drawings, confirmation, and pass it to Hörmann’s production system.

- Rush Orders: Shorter turnaround is available for some standard models. Must be arranged early with your sales contact.

- Delays Possible: Production may slow down during high order volumes, especially late fall and winter. Custom glass and finishes can also affect timelines.

Supply Chain & Logistics

Hörmann operates 26 plants worldwide, including several in Germany. All composite doors are made in their European factories with consistent quality control.

They source raw materials like steel, aluminum, and insulation from long-term partners. This helps them keep delays and defects low. Most hardware is sourced from within Europe.

Logistics are handled through local dealerships. They assist with site delivery, freight planning, and customs paperwork. I’ve found this helpful when managing projects outside the EU.

Final Verdict

Hörmann is best for hotels, gated homes, and commercial sites where strength and clean finish matter. However, since you must go through official dealers, early coordination is key.

3. Vallisco

I’ve worked with a lot of suppliers in China, but Vallisco stood out from the start. Their team responds fast, sends clear drawings, and delivers what they promise. That’s not something you get every day.

Vallisco is a new brand, launched in 2024 under the Qijia Group, a company with over 15 years in door and window production. They focus on high-performance systems for villas, hotels, and housing projects across Southeast Asia and Europe.

They offer factory-direct supply. That means you get pricing without middlemen and full control over design, packaging, and logistics. If you’re running a renovation or a multi-unit building, it makes your life easier.

Product Range

- Double Rebated Composite Entry Door: 70mm thick slab with dual compression seals. Stops drafts and moisture. Good for houses in windy, wet, or high-altitude areas.

- Slim Swing Door: A minimal frame design with full glass insert. Clean, modern, and works well for hotel side entries or garden-facing villas.

- Thermal Break Sliding Door System: Double-glazed sliding doors with thermal barrier. Great for patio spaces in tropical or cold regions where heat control matters.

- Garage Door with Composite Finish: Uses layered composite panels over steel frame. Matches main entry design. Ideal for residential homes that want full style coordination.

Lead Times & Production Turnaround

- Average Production Time: Most orders are ready in 25 to 35 days, depending on volume and product mix.

- Order Workflow: Starts with quotes and drawings. Then comes contract, sample (if needed), mass production, QC, and shipping.

- Rush Orders: Available for standard frame sizes and glass options. Can cut lead time by 5 to 7 days.

- Delays Possible: Custom colors, oversized glass, or slow client-side approvals may extend turnaround. Freight booking delays can also affect timing.

Supply Chain & Logistics

Vallisco operates under Qijia’s factory network in Foshan. They produce doors and windows in-house, using local and imported materials. This gives them control over cost, quality, and finish.

Shipping is available by sea, air, or land, depending on the order size and your location. They provide all packaging, labeling, and paperwork for customs. I’ve found their team fast to respond when you need freight quotes or shipping documents.

If you need your logo on cartons or delivery scheduled in batches, they’ll help with that too. Their team works directly with your engineering or sourcing staff to avoid miscommunication.

Final Verdict

Vallisco is a smart pick for hotels, villas, and house projects needing factory-direct support. However, as a new brand, they’re still building their global track record, so you might not find as many third-party reviews yet.

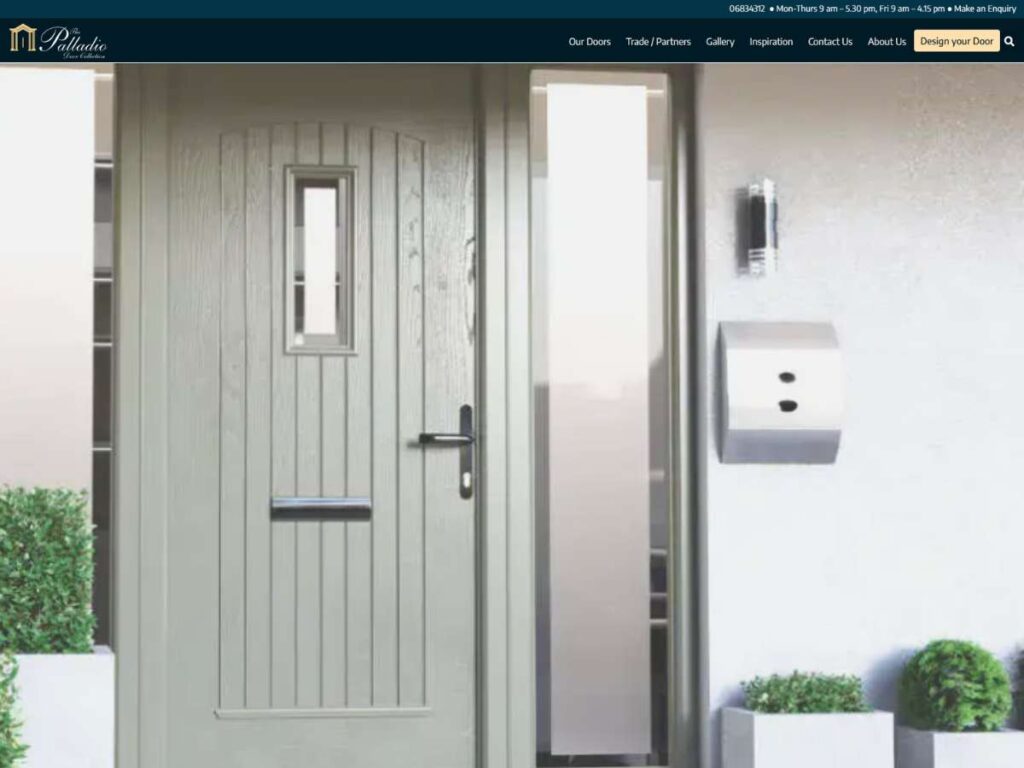

4. The Palladio Door Collection

The first time I used Palladio doors was for a guesthouse project in the UK. The client wanted something traditional, but with modern insulation. Palladio checked both boxes.

They’ve been producing doors since 1984. That gives them over 40 years of hands-on experience in the composite door industry. While they mainly serve Ireland and the UK, their reputation has started to grow across Europe too.

Product Range

- Double Rebated Composite Door: 70mm thick with twin rebated seals. High insulation and security. Works well for homes and buildings in cooler or windier areas.

- Rome Style Door: A curved top panel with decorative glazing. Looks great in traditional villas or inns that want a soft, classic entry.

- Georgian Collection: Doors with symmetrical designs, raised panels, and heritage look. Useful for townhouses or guest lodges with a historical style.

- Cairo Style Door: Contemporary with slim glass inserts. Matches modern hotel builds or homes with clean exterior lines.

- Side Panels & Fanlights: Add-ons that match the door slab. Let in more light. Helps create wide, welcoming entries for hotels or lobby spaces.

Lead Times & Production Turnaround

- Average Production Time: Most orders take 3 to 5 weeks, depending on size and design details. Common styles move faster.

- Order Workflow: You work through local partner installers. They handle the order, measurement, and coordination with Palladio’s factory.

- Rush Orders: Some installers offer quicker turnaround for urgent projects. This depends on local inventory and factory schedule.

- Delays Possible: Custom glazing, special colors, or multi-panel sets can stretch the timeline. Holidays also slow production.

Supply Chain & Logistics

Palladio produces its doors in Ireland. They use reinforced fiberglass skins and a monocoque structure that adds strength and durability. This helps prevent warping, even in areas with big weather changes.

Distribution is handled through approved trade partners. These installers usually manage the delivery, unpacking, and fitting. For larger builds, the factory can coordinate with project engineers or general contractors directly.

While they don’t ship internationally by default, they may support bulk orders outside Ireland and the UK if you reach out with project details.

Final Verdict

Palladio is best for classic villas, inns, and small hotels looking for beauty and strength in one. Just note that since they work mainly through local installers, international buyers may need to coordinate more.

5. Comp Door

I got introduced to Comp Door during a mid-size villa project in Manchester. We were on a tight schedule and needed something solid, energy-efficient, and easy to fit. Comp Door delivered on all three.

They’re a fairly new name in the UK market but backed by people with long experience in door manufacturing. What makes them different is their 70mm timber-core door slab with a wet-glazed system. That helps stop leaks and keeps the glass secure, something installers really appreciate.

Product Range

- 70mm Double Rebated Composite Door: Main product line with timber core, twin seals, and triple glazing. Built for thermal performance. Good for both new builds and replacements.

- Solid Color Collection: Doors in bold colors like blue, green, or black. Work well in villas or guesthouses that want to stand out from the street view.

- Traditional Door Styles: Features like woodgrain texture, panels, and classic letterplates. Great fit for older homes or inns needing energy upgrades without losing charm.

- Contemporary Styles: Sleek and simple. Long glass inserts and steel handles. Popular in city hotels and new housing projects.

- Side Panels & Top Lights: Add-ons for larger entries. Helps open up space while keeping the door weather-tight. Often used in hotel lobbies or villas.

Lead Times & Production Turnaround

- Average Production Time: Most orders ship within 2 to 3 weeks, especially if you’re using standard colors and styles.

- Order Workflow: You build the door online through their trade portal, confirm specs, and approve the final drawing for production.

- Rush Orders: Faster turnaround available for trade partners. Some orders ship in as little as 7 working days if stock permits.

- Delays Possible: Custom paint finishes, unusual glass, or changes during approval can push timelines back.

Supply Chain & Logistics

Comp Door handles manufacturing from their UK site. They use timber cores with bonded skins and certified components. That gives them control over every part of the build.

Their supply chain is built for quick, domestic delivery. Products are packed and shipped via pallet or direct-to-site transport. They also allow batch ordering, which helps when you’re coordinating larger installations.

While they currently focus on the UK market, they may support export requests for bulk orders. You’d need to reach out to the sales team for terms.

Final Verdict

Comp Door is ideal for contractors, installers, or small developers looking for strong, thermally efficient double rebated doors on short timelines. Since they’re newer to the market, their international reach is still growing.

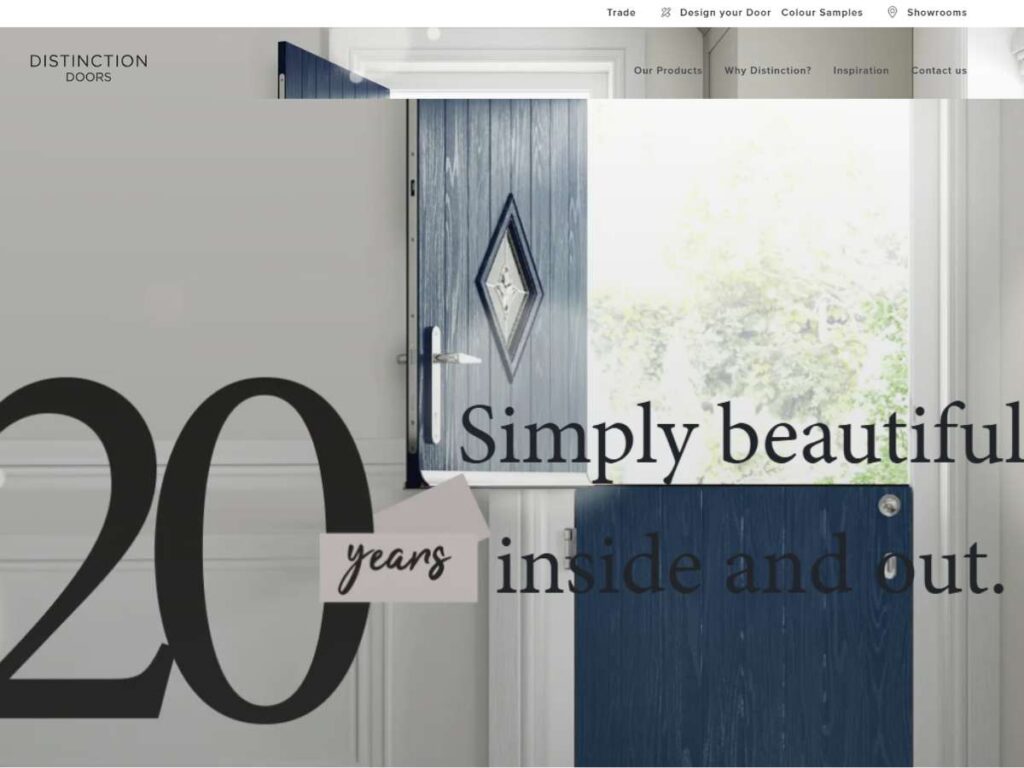

6. Distinction Doors

I came across Distinction Doors during a townhouse renovation in northern England. The project needed something reliable and cost-efficient that could still give a solid feel. Distinction checked those boxes.

They’ve been supplying composite door slabs since 2004. Their 70mm double rebated range became popular with installers looking for extra thermal and noise protection. What stands out is their smooth delivery process and wide color options. Their slab design is also compatible with most PVCu systems, which helps when working with fabricators.

Product Range

- 70mm Double Rebated Composite Slab: The main product with twin compression seals and foam core. Strong insulation and better sealing than single rebate doors. Used in both homes and hotels.

- Signature Colour Collection: Includes woodgrain, bold shades, and pastel tones. Helps match local design codes or client taste without needing repainting.

- Architectural Glass Designs: Glazing choices for modern or classic looks. Good for front entries in guesthouses, villas, or stylish inns.

- Fire-Rated Composite Doors: Certain models meet fire-resistance requirements. Suitable for internal zones, apartment entries, or staff-only access doors.

- Compatible Framing System: Their slabs fit with many UK frame setups, which helps cut install time. Useful for fabricators who want to mix and match.

Lead Times & Production Turnaround

- Average Production Time: Lead time is usually 10 to 20 working days for most standard slab orders depending on finish and season.

- Order Workflow: Orders are placed by trade customers or fabricators, who then match the slab with custom frames and hardware.

- Rush Orders: Available in some cases, especially for repeat buyers or bulk orders using stock colors and glass.

- Delays Possible: Bespoke color matching, special glass orders, or logistics backups can slow delivery slightly.

Supply Chain & Logistics

Distinction runs their production and storage from a large facility in Rotherham. They use composite skins bonded to foam cores and work with approved suppliers across the UK.

Their logistics system supports pallet delivery for small or bulk slab orders. Many of their customers are fabricators who then assemble and deliver final doors. While they don’t ship full door sets themselves, they work closely with trade partners who do.

International delivery is rare, but possible for large, one-time projects. You’ll need to reach out directly to confirm support outside the UK.

Final Verdict

Distinction Doors is a solid fit for trade customers, fabricators, and property developers working on repeat housing units or hotel refits. However, since they mostly sell slabs, not full doors, you’ll need your own framing and fitting setup.

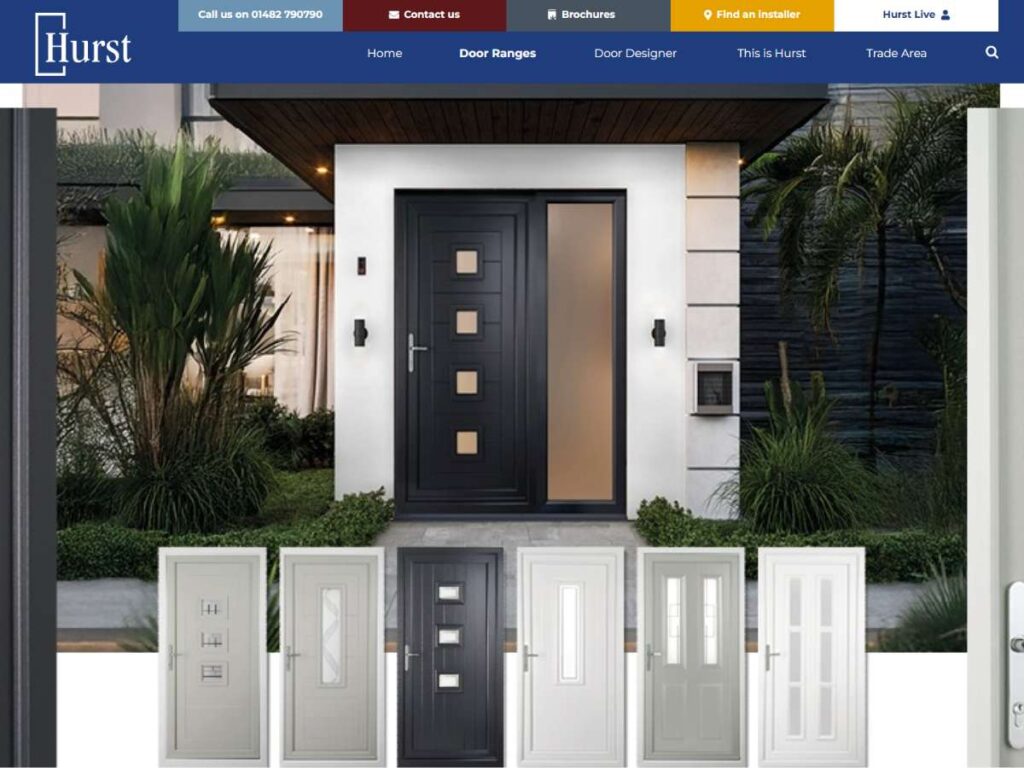

7. Hurst Doors

I first worked with Hurst when we had a fast turnaround project, a small hotel upgrade with 12 rooms. We needed strong, reliable doors that could arrive quickly. Their trade team helped us sort everything from spec to delivery.

Hurst has been operating since 1996 and supplies thousands of composite doors across the UK every month. Their factory runs at high capacity but still manages to give each order proper care.

What’s useful is their focus on the trade. You get support from the quoting stage all the way to post-delivery. They also offer helpful tools like online ordering and fast production tracking.

Product Range

- Double Rebated Composite Doors (70mm): These come with two compression seals for better insulation. Good for weather-exposed buildings or rooms that need temperature control.

- Decorative Glass Options: Offers bevels, privacy glass, and etched designs. Adds style to hotel entries or villa doors without needing custom fabrication.

- Stable Door Options: Doors that open in 2 parts. Useful for garden-access guest rooms or homes with pets and children.

- Fire Rated Door Collection: Certified for internal safety zones. Can be used in hallways or staff-only areas that need compliance.

- Door Panels and Side Lights: Available to match entry doors. Helps widen the look while keeping seals tight and energy use down.

Lead Times & Production Turnaround

- Average Production Time: Most standard orders are produced within 5 to 7 working days. One of the fastest in this category.

- Order Workflow: Trade customers use an online portal to configure, price, and place orders. Confirmation triggers immediate production scheduling.

- Rush Orders: Express turnaround is available for in-stock styles and colors. Can be ready in under a week.

- Delays Possible: Lead time may extend during holidays or if custom glass or non-stock frames are selected.

Supply Chain & Logistics

Hurst manufactures all doors at its main facility in Hull. They source composite slabs, glazing units, and hardware from approved UK and European partners.

Orders are shipped via pallet or direct trade delivery. Larger batches are split and labeled for easy site handling. This is helpful when working on multiple units or phased construction.

International delivery isn’t part of their regular service, but if you’re managing a large export project, their sales team may be able to support special arrangements.

Final Verdict

Hurst is a strong match for UK-based builders, trade installers, and developers working under time pressure. While their international logistics are limited, they shine in fast local delivery, solid door options, and helpful trade tools.

Conclusion

I’ve worked through the challenges, tested the suppliers, and shared what I’ve learned. Finding the right door manufacturer doesn’t have to be a guessing game.

Whether you need fast turnaround, thermal performance, or long-term support, this list gives you real options.

If you’re still unsure where to start, Vallisco offers factory-direct service with flexible designs, and they speak your language.

You’ve seen the full breakdown, now go back and match the right supplier to your next project.

Contact Vallisco today and let’s get your build moving.

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.