I once had to replace 10 doors in my small inn after a single storm season. The old ones warped so badly that guests complained every day. It was a stressful and expensive mistake.

That pushed me to look for manufacturers who can deliver doors that last in real condition. I realized many owners face the same challenge.

That’s why I’ve taken the time to review suppliers who actually stand behind their products. What I share here is based on solid checks and years of handling projects like ours.

This article lists 7 polywood PVC door manufacturers you can count on for projects in hotels, villas, and houses. By the end, you’ll know who offers the quality and consistency you need.

If you’ve ever dealt with repairs or replacements too soon, you know how much it affects your business.

Let’s dive in!

Quick Comparison Chart

As a hotel owner, I learned that choosing the right polywood PVC door manufacturer saves time, money, and guest complaints. A reliable supplier makes all the difference.

Here’s a simple comparison of seven top polywood PVC door manufacturers:

| Manufacturer | Product Range | Durability | Pricing Level | Customer Type Focus | Best for |

| Dhabriya Polywood Ltd | doors, frames, panels | long-lasting | mid-range | hotels, villas | wide product types |

| Doorwin Windows Inc | doors, windows | high | premium | villas, B&Bs | custom project flexibility |

| Vallisco | PVC, aluminum door lines | high | premium | hotels, luxury homes | modern high-end doors |

| JKD Plastics | doors, profiles | good | affordable | houses, greenhouses | strength and style balance |

| VEKA (via PVC suppliers) | PVC profiles for doors | high | mid-premium | large projects | international profile systems |

| Royal Home Group Inc | PVC/MDF/WPC doors | moderate | low-mid | houses, villas | factory-direct pricing |

| AMEX-BĄCZEK | PVC/aluminum door systems | high | mid-range | hotels, apartments | EU-focused PVC door systems |

Explore the full review for deeper insights and to match the right manufacturer with your project needs.

1. Dhabriya Polywood Ltd

Contact Info

- website:https://www.polywood.org/

- Location: Jaipur, Rajasthan

- email:enquiry@polywood.org

Overview

As a hotel owner, I care about steady supply and clear drawings. Dhabriya Polywood has made PVC and uPVC products for decades. Teams know large orders need timing, sizing, and quick answers.

They run extrusion and finishing in-house. That helps with consistency and lead times on door sets and matching trims. You get samples, drawings, and a single point of contact. For projects like yours, that simple path saves time.

Products & Services

Products

- uPVC/PVC doors

- Door and window profiles

- Wall and ceiling panels

- SPC and laminate flooring

- Decorative sheets and moldings

Services

- Extrusion and lamination

- Custom section design

- Shop drawings and sample approval

- Project supply coordination

- After-sales support

Quality Control & Assurance

- Raw Materials & Traceability: PVC and uPVC compounds are processed in-house. Controlled batches and checks are used. Ask for lot numbers, supplier certificates, and labels on every shipment.

- Manufacturing Standards: Extrusion, lamination, and printing lines support consistent sections and finishes. Request standard operating procedures, calibration records, and pre-production sample approvals tied to your drawings.

- Testing & Verification: Internal labs handle dimension checks and inspection before packing. For tenders, ask for third-party reports on impact, moisture resistance, and thermal performance for each model.

- Third-Party Audits: As a listed company, corporate filings are public. Request current ISO certificates, CE/DoP (if EU), and any factory-audit summaries relevant to your order.

- Defect/Recall History: No formal recalls surfaced in common portals. Ask for defect metrics, warranty claim rates, and corrective actions by model to guide risk planning and spares.

- Customer Feedback & Resolution: Use the enquiry channel for after-sales. Ask for project references, escalation contacts, and written response times before award to keep issues small.

Certifications & Compliance

Dhabriya Polywood publishes governance documents as a public company. That transparency helps buyers review policies before placing large orders.

Product certifications can differ by line and destination. Match certificates to your specification. Keep copies with drawings, packaging marks, and batch labels for site checks.

If you export to the EU, request CE/DoP by model. For other regions, align reports with local standards and fire or emissions rules.

Research & Development

- In-House vs. Collaboration: Design and extrusion work happen in-house, including dies and tools for door sections. External labs support validation and market access on export models when needed.

- Product Development Process: New surface finishes and printed patterns move from trials to production after reviews. Drawings and physical samples are shared for approval before mass orders.

- Testing New Products: Prototype sections undergo dimension checks, heat exposure, and impact tests. For projects, request third-party test reports that match your technical schedule.

- Adaptability to Trends: Catalog updates reflect hotel and housing requests, like fluted panels and marble-look sheets. Lines expand to meet timelines and coordinated interior themes.

- Patents/Technology: Public sources list no patents. Ask about proprietary profiles or licensed hardware. Secure drawings and change control inside the contract package.

Final Thoughts

For India or nearby markets, Dhabriya fits projects needing many PVC/uPVC door sets with matching panels and trims. You get scale and a clear contact path. However, public detail on batch tracking is limited; that said, you can close the gap by requiring labeled samples, full certificate packs, and an agreed inspection and escalation plan in your purchase order.

2. Doorwin Windows Inc.

Contact Info

- Website:https://www.doorwinwindows.com/

- Location: Anaheim, CA

- Email:support@doorwingroup.com

Overview

As a hotel owner, I need clear drawings, steady lead times, and neat packaging. Doorwin offers aluminum and PVC/uPVC doors and windows for project work. Their team shares shop drawings and coordinates shipments.

You can visit a Texas showroom for samples and support. That helps when you want to touch hardware and check finishes before a big order. For busy projects like yours, quick answers matter.

Products & Services

Products

- Aluminum doors and windows

- PVC/uPVC doors and windows

- Tilt-turn, sliding, casement, and bi-fold lines

- Glass packages for energy goals

- Hardware options and colors

Services

- Shop drawings and take-offs

- OEM/ODM customization

- Showroom consultation

- Export packing and logistics support

- After-sales email support

Quality Control & Assurance

- Raw Materials & Traceability: Ask for batch labels on frames, glass, and hardware. Keep a packing list that links lot numbers to drawings. It makes warranty and spares much simpler.

- Manufacturing Standards: Factory teams use drawings and checks to keep sizes consistent. Request work instructions, calibration logs, and first-article approvals tied to your project schedule and model list.

- Testing & Verification Processes: Some models carry NFRC, CSA, and Energy Star test data. Match reports to exact SKUs and glazing so your submittals pass in one round.

- Third-Party Audits & Verifications: Use official directories or lab reports to confirm ratings. Keep PDF copies with elevations, glass build, and hardware notes for site inspectors.

- Defect Rates & Recall History: Public recall notices were not found. Still, ask for monthly defect metrics and corrective actions for frames, seals, and finishes across the last four quarters.

- Customer Feedback & Complaint Resolution: Use the showroom and email channel for escalations. Agree on response times, spare parts rules, and who signs off fixes during installation.

Certifications & Compliance

Doorwin markets products with NFRC/CSA/Energy Star data on selected lines. Treat those as model-specific. Always confirm the exact profile, glass package, and spacers in the reports.

For EU jobs, ask for CE and a DoP per door or window type. Keep certificates, drawings, and labels together in your submittal pack to speed approvals.

If your site needs hurricane, acoustic, or fire results, request the right test numbers before you lock the PO. That avoids late changes.

Research & Development

- In-House vs. Collaboration: Core design happens in-house. External labs validate performance for target markets, which helps with permits and energy credits on bigger projects.

- Innovation & Product Development Process: Teams iterate from drawings to samples, then pilot runs. You review hardware, finishes, and glass details before they scale a line for your order.

- Testing Procedures For New Products: Prototype units get measured, glazed, and sent for third-party tests when required. Ask for the latest report set tied to your exact configuration.

- Adaptability To Market Trends: Offerings cover aluminum and PVC/uPVC with many opening types. That makes switching styles easier when architects change specs late.

- Patents Or Proprietary Technologies: Patents are not listed publicly. Ask if any profiles or hardware are licensed, and documents change control inside the contract.

Final Thoughts

For North American projects that need showroom access and fast drawing support, Doorwin can fit well. You get many options and model-level test paths. However, some certificates are product-specific; therefore, lock the exact SKUs, glazing, and labels in your submittals, and require copies from official directories before production.

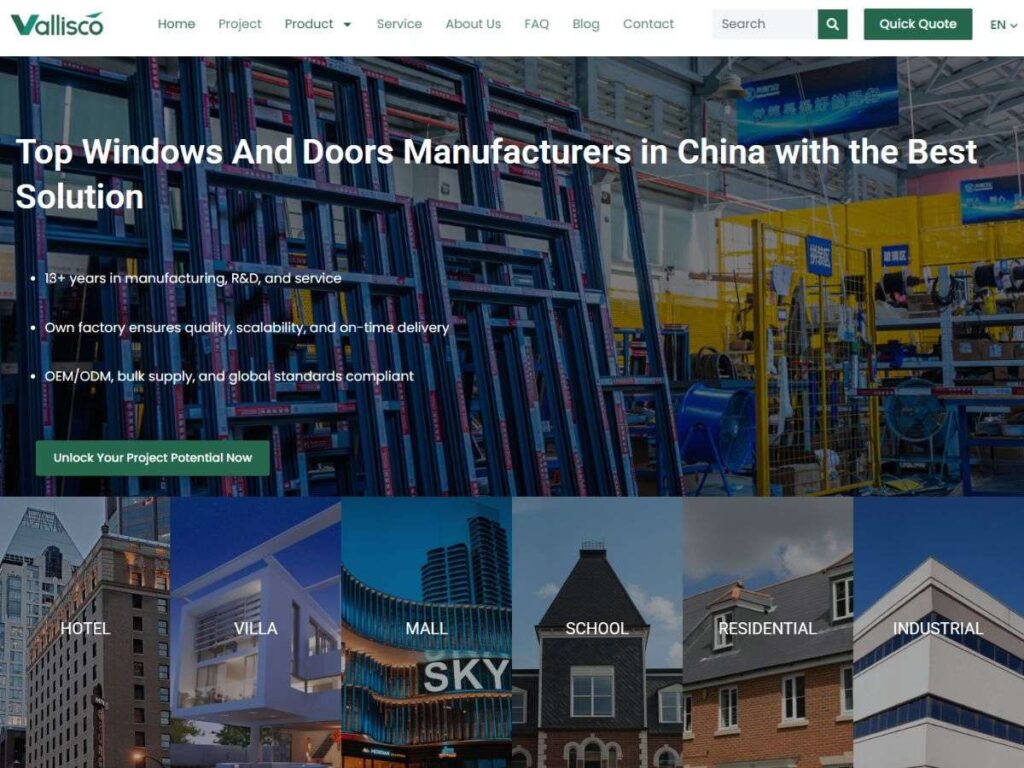

3. Vallisco

Contact Info

- website:https://vallisco.com/

- Location: No. 1926, Cao An Highway, Jiading District, Shanghai, China

- email:kelly@vallisco.com

Overview

As a hotel owner, I want straight answers and factory access. Vallisco is a factory-owned brand serving B2B projects across Southeast Asia and Europe. The team shares drawings, samples, and quick quotes.

The brand was launched in 2024 under Qeeka Home, with staff bringing years of manufacturing experience. For project buyers like you, that mix of fresh energy and seasoned production can help with timelines and consistency.

Products & Services

Products

- Doors

- Windows

- Aluminum doors and windows

- Iron doors

- Garage doors

Services

- OEM/ODM customization

- Shop drawings and sample packs

- Project coordination and export packing

- After-sales email support

- Regional shipping guidance

Quality Control & Assurance

- Raw Materials & Traceability: Factory-owned production gives clearer line of sight into profiles, hardware, and finishes. Request batch labels and supplier certificates to track shipments against drawings and elevations.

- Manufacturing Standards and Best Practices: Standardized extrusion, fabrication, and surface processes support sizing and finish consistency. Ask for work instructions, calibration logs, and first-article approvals linked to your project.

- Testing and Verification Processes: Product pages reference performance aims. For tenders, ask for third-party test reports on impact, moisture, thermal, and acoustic values that match exact SKUs and glazing.

- Third-Party Audits and Verifications: The team cites export experience. Request current ISO certificates and CE/DoP by model, plus any factory-audit summaries relevant to your destination market.

- Defect Rates and Recall History: As a 2024 brand, long-term public data is limited. Ask for quarterly defect metrics, corrective actions, and warranty claim rates to guide risk and spare planning.

- Customer Feedback and Complaint Resolution: Use the direct email for escalations. Agree on response times, replacement rules, and labeling standards before award to keep installation issues small.

Certifications & Compliance

Vallisco markets export-ready lines and says it serves projects across Southeast Asia and Europe. Treat paperwork as model-specific. Ask for current documents with every order. (Vallisco)

For EU jobs, request CE and a DoP per door type. Keep certificates, labels, and drawings together in submittals. That helps pass checks faster.

For other regions, align reports with local building, fire, and emissions rules. Match test numbers to exact configurations.

Research & Development

- In-House vs. Collaboration: Core design, fabrication, and finishing happen in-house. External labs are engaged as needed to validate performance for export and permitting.

- Innovation and Product Development Process: Teams move from drawings to samples, then pilot runs. You review hardware, finishes, and glass details before full production on your order.

- Testing Procedures for New Products: Prototypes are measured and checked for fit and finish. Request lab reports tied to your exact glass build, profile, and hardware set.

- Adaptability to Market Trends and Demands: The catalog spans PVC, aluminum, uPVC, and iron lines. Switching styles late is easier when architects revise specs.

- Notable Patents or Proprietary Technologies: No public patents listed. Ask about proprietary profiles or licensed hardware, and set change control inside the contract.

Final Thoughts

For villa and hotel projects needing a direct factory partner and quick samples, Vallisco fits well. You get clear contacts and many door system choices.

However, as a new brand, third-party reviews and long-term field data are still thin; therefore, reduce risk by piloting a small lot first, tightening acceptance criteria, and requiring complete certificate packs before full release.

4. JKD Plastics

Contact Info

- Website:https://www.jkdplastics.com/

- Location: Panipat (Haryana) India

- Email:sales@jkdplastics.com

Overview

As a hotel owner, I need parts that arrive on time and fit right. JKD Plastics makes WPC and PVC doors, frames, and boards in Panipat, India.

They sell across India and export. Founded in 2014, the company lists ISO 9001:2015 on its site. Communication stays simple through a single sales email. For projects like yours, that steady contact helps with drawings, samples, and shipping plans.

Products & Services

Products

- WPC doors

- WPC door frames

- PVC foam boards

- WPC boards

- PVC trim boards

Services

- Custom sizes and colors

- Project quotations

- Export packing and logistics

- Distributor supply

- After-sales email support

Quality Control & Assurance

- Raw Materials & Traceability: Use batch labels and supplier certificates to trace frames and boards from plant to site, linking deliveries to drawings and rooms for replacements and claims.

- Manufacturing Standards: Extrusion and lamination lines support sections and finishes. Ask for work instructions, calibration logs, and first-article approvals tied to project drawings, hardware sets, and packaging.

- Testing & Verification: Internal checks cover dimensions and appearance before packing. For bids, request third-party reports for impact, moisture, thermal, and emissions that match your models and configurations.

- Third-Party Audits & Verifications: Site claims ISO 9001:2015. Ask for certificates, scope pages, and auditor details. If exporting, request CE or local compliance files matched to each ordered model.

- Defect Rates & Recall History: Public recall data is limited for regional makers. Ask for defect rates, claim figures, and corrective actions by product line to plan spares and time.

- Customer Feedback & Complaint Resolution: Use the sales email to register issues and needs. Agree on response times, replacement rules, and labeling standards before award to keep on-site problems small.

Certifications & Compliance

The site displays an ISO 9001:2015 claim. Always request a current certificate copy, the scope page, and the issuing body. Keep these with your drawings and submittals.

For EU projects, ask for CE and a DoP for each door or frame type. For other regions, match local building, fire, and emissions rules to the ordered models.

Paperwork varies by product line and destination. Tie certificates to exact SKUs, finishes, and hardware lists to speed approvals.

Research & Development

- In-House vs. Collaboration: Core work is in-house: profiles, doors, and frames. For export needs, request third-party lab validation that maps to your drawings, glass builds, and hardware sets.

- Product Development Process: Samples and drawings move first, then pilot runs. Approve sizes, finishes, and hardware lists before scaling. Keep a revision log so production follows approved version.

- Testing Procedures For New Products: Prototype sections undergo dimension checks, heat exposure, and impact tests. Request third-party lab reports aligned to market rules, and attach them to submittals and packing.

- Adaptability To Market Trends: Catalog shows WPC doors, frames, and PVC boards. That mix helps projects shift styles. Confirm lead times for color films and profiles before approving schedules.

- Notable Patents Or Technologies: Patents are not listed. If proprietary profiles exist, ask for drawings and change-control rules. Keep mold numbers, revision codes, and hardware lists inside the package.

Final Thoughts

For hotel and villa work across India, JKD Plastics suits teams wanting WPC doors, frames, and boards from one source with simple contact. You get quick quotes and range.

However, public model-level lab reports can be limited; therefore, lower risk by requiring certificate copies, labeled samples, and a pre-shipment inspection with clear acceptance criteria tied to drawings and packing lists.

5. VEKA (via PVC Suppliers)

Contact Info

- Website:https://www.veka.com/

- Location: Warendorf, Germany

- Email:info@veka.com

Overview

As a hotel owner, I want doors that install cleanly and last. VEKA supplies PVC-U profile systems for doors and windows. Their partners fabricate the finished units you buy. That setup gives you local sourcing with global profile support.

The group has produced profile systems for more than 50 years and backs fabricators with manuals, specs, and digital tools. For project teams like yours, that support shortens submittals and site questions.

Products & Services

Products

- PVC-U door and window profile systems

- Front-door, sliding, and bi-fold profile suites

- Surface options: foils and VEKA SPECTRAL

- Ancillary profiles, trims, and gaskets

Services

- Technical manuals and fabrication guides

- Fabricator training and partner support

- Digital tools and specification resources

- Local partner network for supply and service

Quality Control & Assurance

- Raw Materials & Traceability: VEKA runs an ISO 9001 quality system for profile development and extrusion. Ask for batch records and labels that link delivered lengths to your drawings.

- Manufacturing Standards: Corporate manuals and fabrication guides set profile handling, cutting, and assembly rules. Share these with your fabricator so plant steps match your specs.

- Testing & Verification: Profiles and systems have documented test data. Keep the relevant pages in your submittal pack so inspectors can match sizes, wall classes, and limits.

- Third-Party Audits & Verifications: VEKA holds ISO 9001. Selected systems carry RAL quality marks. Save valid certificates and revision pages with elevations and hardware schedules.

- Defect Rates & Recall History: As a profile supplier, VEKA’s parts feed many fabricators. Track defects at your fabricator and keep corrective-action logs tied to specific profile codes.

- Customer Feedback & Complaint Resolution: Use the VEKA partner finder to select a qualified fabricator. Set response times and replacement rules in the contract before production.

Certifications & Compliance

VEKA AG holds ISO 9001:2015 for development and extrusion of PVC profiles. Keep a current copy in your files. Check validity dates and scope pages each year. (VEKA Deutschland)

Several profile systems appear with RAL quality marks. For your project, match the system name and revision to the certificate list. Attach these to your submittals.

Finished doors and windows are certified by the fabricator, not VEKA. Ask your chosen fabricator for CE/DoP (EU) or local equivalents tied to your exact model. (VEKA Deutschland)

Research & Development

- In-House Labs & Engineering: VEKA develops and validates profile systems, then publishes fabrication guides. These help partners build consistent door sets that match drawings and hardware choices.

- System & Surface Innovation: New suites and surface options, including SPECTRAL and varied foils, support different looks and climates without changing core dimensions.

- Technical Resources For New Products: Specification guides, manuals, and updates give clear limits, testing references, and assembly notes you can attach to contracts and RFQs.

- Adaptability To Market Needs: With many regional partners, you can source locally while keeping profile families consistent across sites and phases. Coordinate SKUs early to keep colors aligned.

- Proprietary Systems: Profiles are VEKA systems; patents are not highlighted on public pages. Request any protected drawings and keep revision control inside the purchase order.

Final Thoughts

If you want Tier-1 PVC-U profiles with a wide partner network, VEKA is a strong path. You gain manuals, certificates, and local fabrication options. However, performance and labels depend on the fabricator you pick; therefore, select an audited partner, tie manuals to the contract, and require model-specific certificates with every shipment.

6. Royal Home Group Inc.

Contact Info

- Website:https://royalsdoors.com/

- Location: Zhejiang Province, China

- Email:info@royalsdoors.com

Overview

As a hotel owner, I need clean installs and steady schedules. Royal Home Group makes MDF PVC doors, WPC frames, and other interior sets. They also offer free samples and quick replies, which helps with early choices.

The factory operates in Jiangshan, Zhejiang, with additional capacity noted on site. For you, that can simplify color matching and sizes across many rooms during phased work.

Products & Services

Products

- MDF PVC interior doors

- WPC doors and frames

- Melamine/painted door lines

- Door skins and panels

- PVC profiles

Services

- OEM/ODM customization

- Shop drawings and samples

- Export packing and logistics

- Free samples program

- Email support with fast responses

Quality Control & Assurance

- Raw Materials & Traceability: Factory production includes membrane and PVC lines. Request batch labels and supplier certificates linking pallets to drawings and hardware lists so shipments match site plans.

- Manufacturing Standards: Standardized pressing, lamination, and finishing steps guide sizes and surfaces. Ask for instructions, calibration logs, and first-article approvals tied to drawings and packaging before production.

- Testing and Verification Processes: Site materials describe features of PVC and MDF doors. To reduce risk, request third-party lab reports for moisture, formaldehyde, impact, and thermal results matching SKUs.

- Third-Party Audits and Verifications: The company lists ISO, CE, SONCAP, and SGS. Request certificates, scope pages, and model mappings, then archive PDFs with elevations and hardware for inspectors later.

- Defect Rates and Recall History: Check public recall portals for your markets before award. Request quarterly defect metrics and corrective actions by product line to plan spares, warranties, and contingencies.

- Customer Feedback and Complaint Resolution: Use info email for escalations and updates. Agree on response times, replacement rules, and labeling standards upfront so installers can match parts quickly during turnovers.

Certifications & Compliance

Site pages claim ISO, CE, SONCAP, and SGS. Treat these as line-specific. Ask for current copies and scope pages, then file them with drawings and packing lists.

For EU jobs, request CE and a DoP for each ordered model. Keep the DoP numbers tied to exact SKUs, finishes, and hardware in your submittals.

Other regions have local rules on fire, emissions, and labeling. Match reports to those standards before production starts.

Research & Development

- In-House Vs. Collaboration: Core design and fabrication are in-house, covering MDF PVC and WPC lines. When targeting markets, engage external labs to validate performance and help with permits.

- Innovation And Product Development Process: Teams move from drawings to samples, then pilot runs. You review finishes and hardware choices, confirm sizes, approve packing, and sign off before scaling production.

- Testing Procedures For New Products: Prototype doors are measured and inspected for surface, fit, and stability. For export, request lab reports tied to specific SKUs, glass builds, and hardware configurations.

- Adaptability To Market Trends And Demands: Catalog shows MDF PVC, WPC, melamine, and painted lines. Custom options support late architectural changes, with color films and surfaces to match styles across markets.

- Notable Patents or Proprietary Technologies: Public pages describe membrane pressing process using high pressure and furnace heat. Patents are not listed; request profile details and document change control inside contracts.

Final Thoughts

For high-volume interior sets, Royal Home Group fits buyers needing OEM/ODM flexibility, free samples, and quick email responses. That helps early decision making.

However, because documentation varies by model and destination, you may face paperwork gaps; therefore, lower risk by requiring certificate packs up front, mapping reports to SKUs, and adding a pre-shipment inspection with clear acceptance criteria.

7. AMEX-BĄCZEK

Contact Info

- website:https://amex-baczek.com/

- Location: Warmian-Masurian Voivodeship

- email:contact@amex-baczek.com

Overview

As a hotel owner, I value clear drawings and steady supply. AMEX-BĄCZEK manufactures PVC and aluminum window-door systems, including PVC doors built on well-known European profile families. Their production lines, catalogs, and partner resources support projects across Europe.

You get system choices, panel doors, and sliding options with technical materials ready for submittals. That helps your team move faster from quote to install.

Products & Services

Products

- PVC door and window systems

- Panel entrance doors

- Tilt-and-slide/PSK and patio doors

- Folding and sliding door sets

- Aluminum door systems

Services

- Technical catalogs and drawings

- Fabrication and packaging for export

- Dealer/partner support

- Project quotations

- After-sales email support

Quality Control & Assurance

- Raw Materials & Traceability: PVC systems use branded profiles and documented components. Ask for batch labels on frames, glass, and hardware, linked to elevations for smooth claims and spares.

- Manufacturing Standards: Production on modern lines with process guidance. Request work instructions, calibration logs, and first-article approvals matched to your drawings and hardware schedules.

- Testing & Verification Processes: Certificates of performance and ITB listings appear on the site. Keep copies tied to exact models and door types in your submittal pack.

- Third-Party Audits & Verifications: CE and EN standard references are published for specific door systems. Confirm certificate numbers, revision dates, and scope before award.

- Defect Rates & Recall History: No public recalls surfaced. Ask for quarterly defect metrics and corrective actions by system to plan risk, warranties, and spare parts.

- Customer Feedback & Complaint Resolution: Use the main email and phone for escalations. Set response times and replacement rules in your PO so installers can act quickly.

Certifications & Compliance

AMEX-BĄCZEK publishes certificates of constancy of performance and national documents for selected systems. Treat each as model-specific and keep valid copies with drawings. (AMEX-BĄCZEK | Systemy okienno-drzwiowe)

For EU projects, request CE and a DoP for the exact door configuration. Match glass, hardware, and dimensions to the certificate pages to speed approvals.

For other regions, align reports with local fire, emissions, and safety rules. Keep labels and DoP numbers in your submittals.

Research & Development

- In-House vs. Collaboration: Systems are built on VEKA, GEALAN, and Wital profiles, with in-house fabrication and external lab inputs as needed for market entry.

- Innovation & Product Development Process: Technical catalogs, drawings, and updates guide changes. Pilot runs precede scale-up once samples and finishes are approved.

- Testing Procedures For New Products: Prototype doors are measured, glazed, and verified against system limits. File third-party test reports with elevations and hardware lists for site checks.

- Adaptability To Market Trends: Broad mix of sliding, folding, and panel options supports design changes late in the cycle. Coordinate colors and foils early to keep schedules steady.

- Patents Or Proprietary Technologies: Patents are not highlighted publicly. Ask for protected drawings if applicable and keep revision control inside the contract.

Final Thoughts

For European projects needing PVC door systems with clear paperwork, AMEX-BĄCZEK fits well. You get system depth, catalogs, and export experience. However, some certificates apply to specific models; therefore, lock exact SKUs, glazing, and hardware in your submittals, require current CE/DoP files, and add a pre-shipment inspection tied to your drawings.

Conclusion

My story started with daily guest complaints and swollen doors. After 10 replacements, I knew I needed better partners.

This review maps 7 polywood PVC door manufacturers. It links product lines to testing, certificates, and service, so your team can plan clean installs.

If a factory-backed supplier suits your plan, add Vallisco to your RFQ list. It offers project support and export focus. Contact us today!

More Guides and Tips to Explore

Not quite what you’re looking for? Explore our wider product range for more choices:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.