I remember managing specs for a small inn project where a metal stairwell door was backordered. The substitute looked the same but failed to meet fire code. That mistake led to delays, fines, and an angry client.

That moment showed me how small choices affect the whole timeline and reputation.

Since then, I’ve supported developers and engineering teams across villas, B&Bs, and small hotel chains. I’ve seen what matters when you’re buying dozens of doors across different zones.

In this article, I’ll help you sort through key specs like fire rating, core types, and usage zones. You’ll get a clear view of what matters based on real use cases not just supplier claims.

Small errors can stall big projects.

So let’s begin!

1. What Is a Commercial Metal Door?

A commercial metal door is built for busy areas like hotels, inns, villas, or utility rooms where a regular wood or fiberglass door wouldn’t last. It’s stronger, heavier, and often needs to meet fire safety codes, which isn’t the case for most home doors. I once saw a lightweight door dented within a week at a hotel loading zone replacing it delayed the whole project.

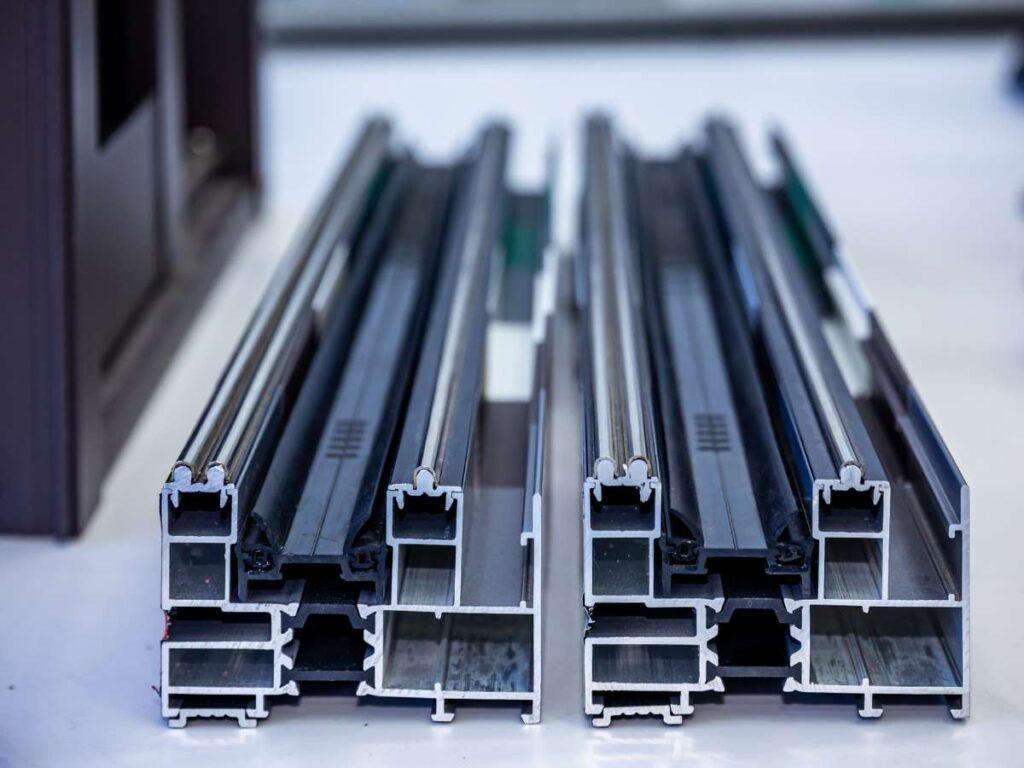

Most commercial metal doors include a metal skin, an internal core, and a matching frame. You’ll often see steel, stainless steel, or aluminum with a honeycomb, steel-stiffened, or insulated core. The right combo affects how the door holds up under wear, moisture, and heat.

2. Types of Commercial Metal Doors

There’s no single type of commercial metal door that works for every project. Some are better for front entrances, while others are made for stairwells, storage rooms, or kitchen service areas. If you’re ordering several doors for different parts of a building, it helps to know what each type is good at. A mismatch between door type and use can lead to costly delays or compliance issues.

Hollow Metal Doors

These are the most common type used in hotels, schools, and commercial spaces. They’re called “hollow,” but they actually have a solid core inside, like honeycomb or steel-stiffened materials. You can use them for both interior and exterior openings, and they’re known for strength, fire resistance, and low cost. For high-traffic areas, this door is often the default pick.

Stainless Steel Doors

If you need something that resists rust and can handle moisture, stainless steel is a good choice. These doors work well in coastal areas, kitchens, hospitals, or any zone with high humidity. On one project near the coast, standard doors started rusting within six months switching to stainless solved that problem fast. They cost more upfront but hold up longer in tough conditions.

Aluminum Doors

Aluminum is lighter than steel and doesn’t rust, which makes it ideal for areas like storefronts or sunrooms. These doors often come with slim frames and glass panels, used more for aesthetics than for impact protection. In entrance lobbies or decorative spaces, they offer a clean look without the weight of steel.

Fire-Rated Doors

These are built to slow down the spread of fire and smoke. They’re required by code in stairwells, kitchen corridors, and mechanical rooms. Always check the fire label rating 45, 60, or 90 minutes based on where the door will go. This detail often gets missed during early planning and ends up causing expensive change orders later.

3. Choosing the Right Material

Not all commercial metal doors are made from the same kind of metal. The outer layer, called the door skin, plays a big role in how the door performs in different environments. You’ll want to match the material to the space indoor guest rooms, outdoor entries, kitchen zones, or high-humidity areas all need different things.

Common Door Skins

Each skin option has its own pros and cons. Here’s a quick breakdown:

- Cold-Rolled Steel: A smooth surface that’s easy to paint, making it popular for indoor use. It’s cost-effective, but not great near moisture or outdoor zones.

- Galvanneal Steel: Coated for corrosion resistance, this works better in coastal areas or semi-outdoor spaces. You can still paint it, and it holds up well in light rain or salt air.

- Stainless Steel: A durable option that resists rust and is easy to clean. Great for kitchens, utility rooms, and stairwells with heavy use or wet mops.

- Aluminum: Lightweight and naturally resistant to rust. Works well for decorative greenhouse entries, sunrooms, or boutique B&Bs that care about curb appeal.

Frame Material Considerations

The frame needs to match the function of the door. A solid steel frame works best in high-security areas or busy commercial zones. Aluminum frames are easier to work with and suit low-impact locations like indoor courtyards or light-use entries.

Final Thoughts

You don’t need to be an expert in metal types, but choosing the right door skin and frame can save time, money, and future repairs. Think about where each door will live and how it will be used. That’s what makes the material choice count.

4. Key Performance Features to Look For

Commercial metal doors might look similar at first, but their performance features vary widely. Some hold up better under daily use, while others help control temperature or improve building security. If you’re managing a project across multiple zones, these details make a noticeable difference in how well each door performs over time.

Durability

Durability starts with the gauge, which refers to the thickness of the metal. A lower number means thicker, stronger door skin.

- 18 Gauge: More lightweight and lower cost. Best suited for light-duty indoor use.

- 14 Gauge: Thicker and more impact-resistant. A better option for high-traffic areas like hotel back doors or storage rooms.

Doors in busy buildings take hits from carts, luggage, and daily wear. If they dent or bend easily, they’ll need replacing far sooner than expected.

Insulation and Energy Efficiency

If energy costs or comfort matter, check the door’s R-value or U-value. These numbers show how well the door resists heat flow. A higher R-value or lower U-value means better insulation.

- Polyurethane Core: Excellent for thermal control. Common in villas and guest zones with air conditioning or heating.

- Polystyrene Core: A more budget-friendly option with solid insulation. Useful for greenhouses or outbuildings.

Insulated doors help regulate temperature and reduce energy waste. They also create a more stable indoor environment.

Security Enhancements

Commercial projects often need stronger door systems to meet safety expectations. Look for these features:

- Reinforced Lock Areas: Extra steel around locks to prevent forced entry.

- Continuous Hinges: Full-height hinges that resist tampering and sagging.

- Multi-Point Locks: Locking mechanisms that secure the top, middle, and bottom of the door.

Choosing the right combination of strength and performance adds value long after the door is installed.

5. Fire Rating & Safety Certifications

Fire safety matters in every commercial project, but it’s especially critical in places where people sleep or gather. Hotels, inns, and guesthouses often need fire-rated doors in stairwells, kitchens, and corridors. These doors are built to slow the spread of fire and smoke, giving people more time to exit and helping first responders do their jobs.

Fire-Rated Door Options

Fire-rated doors are tested to withstand fire for a set period of time. This time rating must match both the building code and the purpose of the room.

- 20 Minutes: These offer basic fire resistance and are often used in corridors or connecting rooms. They provide minimal protection but may meet code in smaller, low-risk areas.

- 45 Minutes: Suitable for storage areas or rooms that don’t connect directly to an exit. This level adds more time for evacuation and keeps flames from spreading too fast.

- 60 or 90 Minutes: Often required for stairwells, shared corridors, or hotel kitchens. These doors add a strong line of defense in case of fire near major pathways.

- 180 Minutes: Used in mechanical rooms, boiler rooms, or high-risk back-of-house areas. These provide maximum protection and are built to withstand extreme conditions.

Don’t forget: the fire label must stay visible on the door. Also, the frame must be rated for the same time period as the door to pass inspection.

Safety Certifications to Check

A fire rating means little without third-party testing. Look for these certification labels when choosing your doors.

- UL (Underwriters Laboratories): This group tests how well products perform in fire and safety situations. If you see a UL label, it means the door passed official fire-resistance tests.

- WHI (Warnock Hersey): Another trusted name in product testing, often seen on commercial doors. A WHI label means the door meets industry safety and performance standards.

- ANSI/BHMA Standards: These standards check things like door strength, impact resistance, and cycle testing. They’re often used by architects and inspectors to verify quality.

Getting the right fire-rated doors isn’t just about following the code. It’s about making safe, smart decisions that protect your building, your timeline, and the people inside.

6. Commercial Applications: Where Each Door Type Belongs

Choosing a commercial metal door isn’t just about specs. It’s also about knowing what works best for each space.

Here’s a breakdown based on different building types. This is the same framework I’ve used when helping property teams plan out dozens of doors across one site.

| Property Type | Recommended Door Type | Best Core Option | Surface / Finish Needs | Special Features to Include |

| Villas / High-End Homes | Cold-rolled or Galvanneal Steel | Polyurethane | Smooth paint-ready surface or woodgrain film | Quiet-close hinges, upgraded handles, weatherstrip |

| Hotels / Inns / B&Bs | Hollow Metal (14–16 gauge) | Steel-stiffened or Honeycomb | Factory-painted or powder-coated | Fire-rated labels, vision panels, sound dampening |

| Greenhouses | Aluminum or Stainless Steel | Polystyrene or Polyurethane | Corrosion-proof, no-paint aluminum or brushed stainless | Lightweight build, moisture resistance, flush bottom |

| Utility / Maintenance Rooms | Steel (14 gauge or thicker) | Steel-stiffened | Scratch-resistant paint or galvanized surface | Louvered panel insert, reinforced lock area |

Each row of the table highlights what the door needs to do whether it’s control temperature, handle abuse, or keep moisture out.

In real projects, mixing door types by zone saves time and avoids rework. It also makes inspections smoother, since every opening has the right spec from day one.

8. Installation Factors: What to Know Before You Buy

You’ve covered the materials, safety needs, and design preferences. But installation is where many door projects fall apart often because of missed measurements or last-minute surprises.

Even a high-quality door can cause delays if it doesn’t fit properly or isn’t built for the wall it’s going into. That’s why planning for installation early makes a big difference.

Frame Compatibility

Start by identifying the type of frame involved.

- Will you use an existing frame or a new one? Reusing a frame is possible if it’s undamaged, aligned, and compatible with the new door. If not, replacing it upfront avoids long-term performance issues.

- Are you working with knock-down or welded frames? Knock-down frames ship in parts and are assembled on-site, making them easier to transport. Welded frames arrive fully assembled and offer greater strength but need more room for delivery and handling.

You’ll also want to take accurate measurements before ordering.

- Wall Depth: This tells you how thick the wall is and determines the throat size of the frame. A mismatch here leads to awkward gaps or poor anchoring.

- Rough Opening Size: Always measure the full opening in the wall, not the old door itself. Even a difference of half an inch can cause fit issues.

- Swing Direction: Stand on the side the door opens away from and check hinge placement. Hinges on the right mean a right-hand door; hinges on the left mean a left-hand door.

Mounting Methods

How the door is mounted affects both function and appearance.

- Surface-Mounted Hinges: These attach to the outside edge of the door and frame, making installation simpler. They are more visible but often easier to adjust or replace.

- Flush-Mounted Hinges: These are recessed into the door and frame for a cleaner look. They are typically used in front-facing or guest-access doors where appearance matters.

Check your door prep details as well.

- Pre-Drilled Holes: Make sure the holes align with the hardware you plan to use, such as handles, locks, or panic bars. If they don’t match, rework or reordering becomes necessary.

- Reinforcement Plates: These are built into the door to support heavier hardware like closers or electronic locks. Without them, the door surface may flex, warp, or fail under stress.

Retrofit vs. New Construction

Whether you’re upgrading an old building or working on a new one affects your door choices.

- Retrofit Projects May Require Extra Work: Older frames can be uneven, damaged, or not rated for the weight of a metal door. You may need custom frame sizes or structural changes to make the new door fit properly.

- New Construction Offers More Flexibility: You can plan exact rough openings, choose ideal swing directions, and prepare mounting surfaces. This makes ordering and installation much more straightforward.

Installing a commercial metal door isn’t just about hanging it on a wall. It’s about matching the frame, hardware, and layout to the door itself before it ever arrives on-site.

9. Safety and Emergency Handling

Metal doors do more than close off a room they play a big role in protecting people. Whether you’re working on a boutique inn, a villa, or a multi-room B&B, it’s not just about how the door looks or how strong it is. You also need to think about what that door needs to do in an emergency.

Missing the right safety rating or hardware can lead to failed inspections, delayed openings, or even denied insurance claims. That’s why it’s important to understand how doors fit into local safety codes from the beginning not just after a problem shows up on-site.

Why It Matters

Every commercial building must follow local building codes for safety. These aren’t just paperwork requirements they’re there to keep guests and staff safe in real situations like fires, power outages, or extreme weather.

If a door is missing a fire label or doesn’t open the right way, it can fail inspection. Fixing that often means reordering parts or tearing out completed work, which adds both time and cost. In some cases, not having the right door could also lead to problems with insurance coverage or legal issues if something goes wrong.

For spaces like hotels and B&Bs, where people may not know the layout or escape routes, following these rules is even more important. That’s why working with a supplier like Vallisco who understands code requirements across different property types can help you avoid costly mistakes and keep your project on track.

Common Requirements

There are a few safety features that show up again and again in commercial projects. Getting these right helps avoid problems later.

- Fire-Rated Doors: Often required in stairwells, hallways, and kitchens. These doors must display a time rating label that meets local code.

- Panic Hardware: Used on emergency exits, this push-bar system lets people exit fast without turning knobs or using keys.

- Weather-Rated Doors: For exterior locations, these doors need to stand up to rain, wind, or temperature swings. They help protect both people and the building.

Always confirm requirements with your local municipality or contractor before placing an order. One small code issue can turn into a large and expensive delay.

10. Choosing the Right Door for Your Property

Choosing the right commercial metal door is about more than checking dimensions. If you’re managing a property with multiple use zones guest rooms, kitchens, utility rooms, or greenhouses you need each door to serve a clear purpose. That decision affects not just the build phase, but inspections, daily operations, and long-term maintenance costs.

Traffic and Use Conditions

Start by thinking about how each door will be used throughout the day. A guestroom hallway door won’t face the same wear as a maintenance room or exterior entry. Lower-traffic areas may allow for lighter-duty options, but service zones often need reinforced cores, heavy-duty hardware, and stronger frames. Matching use conditions with door construction reduces future repair needs.

Door Features With Building Zones

Every zone has different performance requirements. You might need a fire-rated door for a hotel stairwell, but a lightweight, rust-resistant option for a greenhouse entry. Mixed-use projects benefit from coordinating multiple door types to meet code without compromising on design or usability. A supplier like Vallisco can help you balance those needs while keeping specs organized across the entire build.

Balance Safety, Appearance, and Maintenance

In guest-access areas, visual appeal and quiet operation can make a strong impression. But in back-of-house spaces, the focus shifts to security, fire resistance, and durability. Choosing materials and finishes that perform well over time reduces callbacks and keeps the property functioning smoothly even under high use.

Finalize Specs Early in the Build

Waiting until the last minute to finalize door selections often causes delays. A mismatched frame, incorrect swing, or missing hardware prep slows the job and adds cost. When specs are confirmed early, you avoid rushed decisions, meet lead times, and give installers exactly what they need.

The best doors do more than meet code . They support how your building works every day.

Conclusion

That inn project stayed with me for years. One wrong swing direction set the whole job back.

Now you know how to avoid that. From material types to fire codes to fit this guide covered what matters when choosing commercial metal doors.

You’ve got the knowledge. You’ve seen the risks. And you’re not going to make the same mistakes.

Are you ready to spec doors with confidence?

Start your plan now. Choose what fits your property, your budget, and your build timeline.

Need help? Contact us today and let Vallisco guide your next door project from start to finish.

Learn More: Recommended Reads

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.